Welding is a multi-faceted and difficult task. In particular, TIG welding is a bit more tricky and requires skills to weld the metals properly. However, some tips make this difficult task facile for beginners.

Therefore, this article will focus on “TIG welding tips for beginners.” Entry-level people will find the tips and techniques beneficial to hone their skills.

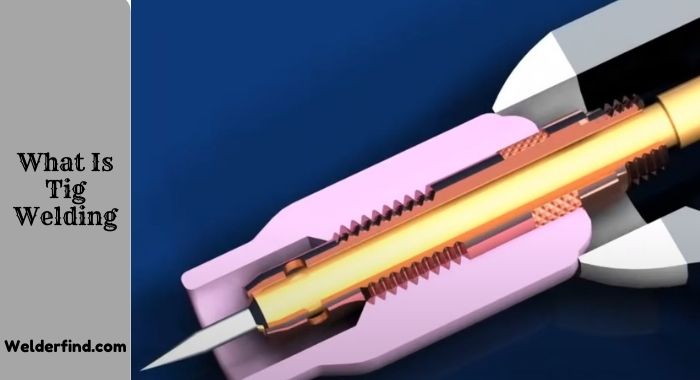

What is TIG welding?

TIG welding refers to an arc welding procedure whereas a non-consumable tungsten electrode generates a welding current to join metals. The process is also familiar as gas tungsten arc welding or GTAW. It can use either alternating current (AC) or direct current (DC), depending on the metals.

During the 1940s, the process got momentum in order to join Aluminum and Magnesium. The entire procedure involves a Power source, Arc starting, Electrodes, and a Shielding gas. The shielding gas generally consists of an Argon and Helium mixture.

What are the 12 Best Tig welding tips for beginners?

Some pro tips can make this difficult task very much predictable and facile for beginners.

Here are the top 12 tips for the readers:

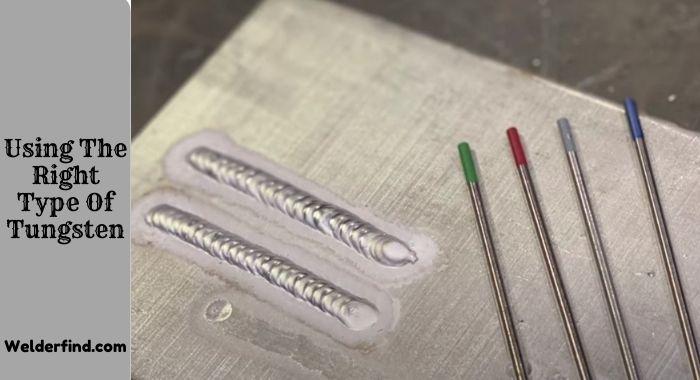

1. Using the right type of tungsten

users will find a variety of tungsten in the market. But success lies in the proper selection of tungsten. Therefore, it is crucial to know about the most used tungsten types before starting the process. Here are some of the key tungsten categories:

- Pure Tungsten:

The most dominant sign of Pure Tungsten is its green ends. Users mostly use them to weld magnesium and Aluminum alloys. Pure tungsten is one of the most used tungsten due to its easier control, use, stable AC welding and affordability. However, this tungsten has a lower current carrying ability and is not convenient for DC welding.

- Thoriated Tungsten

These electrodes consist of 1 to 2 percent of thorium oxide. Unlike pure tungsten, they have either red or yellow ends. This tungsten has wide usage in welding Aluminum alloys, titanium, steel, nickel and stainless steel, .

This tungsten features higher current-carrying capacity, excellent arc stability, and longer durability. Unlike the previous one, this one is also suitable for DC or AC welding. But this tungsten includes radioactive material that poses severe health risks during grinding.

- Ceriated Tungsten

It is one of the most versatile tungsten that users use to weld steel, nickel, stainless steel, and titanium. This tungsten contains cerium oxide as its leading alloying component.

This tungsten is more durable than the pure tungsten. Besides, they provide outstanding arc stability and sufficient resistance to weld pollution.

Like Thoriated Tungsten, this one is also suitable for DC and AC welding. However, they have little current-carrying capacity than the thoriated one.

- Lanthanated Tungsten

People often know this Tungsten as Gold Tip due to their gold ends. They consist of lanthanum oxide. This tungsten has many similarities with Thoriated Tungsten.

However, they are the safer version of Thoriated Tungsten as they contain nonradioactive materials. Users mostly use them to weld nickel, stainless steel, magnesium, copper, carbon steel, titanium, aluminum.

Lanthanated Tungsten features extended electrode durability, excellent arc stability and resistance to pollution. Users can utilize them for both AC and DC welding. However, this one has a lower level of current-carrying capacity than thoriated tungsten and is expensive.

For the readers’ convenience, I have mentioned a table detailing different types of TIG tungsten:

| Name | ISO 6848 classification | Color | Principal Oxide | Oxide mass percent TIG mode |

|---|---|---|---|---|

| Pure Tungsten | EWP/WP | Green | None | N.A |

| Thoriated Tungsten | EWTH-1/WT 10 | Yellow | ThO2 | 0.8-1.2% |

| EWTH-2/WT 20 | Red | ThO2 | 1.7-2.2% | |

| Ceriated Tungsten | EWCe-2/WCe 20 | Grey | CeO2 | 1.8-2.2% |

| Lanthanated Tungsten | EWLa-1/Wla10 | Black | La2O3 | 0.8-1.2% |

| EWLa-1.5/Wla15 | Gold | La2O3 | 1.3-1.7% | |

| EWLa-2/Wla20 | Blue | La2O3 | 1.8-2.2% | |

| Zirconiated Tungsten | EWZr-1/WZr 3 | Brown | ZrO2 | 0.15-1.5% |

| EWZr-8/WZr 8 | White | ZrO2 | 0.7-0.9% | |

| Rare earth Mix | EWG | As per the manufacturer’s choice | manufacturers decide all additives | Manufacturer set quantities |

2. Grind tungsten well

For perfect grinding tungsten, it is vital to select the right grinding wheel. One can choose aluminum oxide wheel with a diameter between 3/4 to 1-1/2 inch for sharpening tungsten electrodes. They will not contaminate them like other tungsten. Then firmly secure it on the grinder.

3. Clean the base metal and workpiece

TIG welding is not suitable for dirty material. Therefore, users must thoroughly clean the metal materials for a better result. Otherwise, the entire welding process will get contaminated and provide an unsatisfactory result.

Different metals require different cleaning mechanisms. One can use a delicate brush to clean aluminum and stainless steel while others may need a detailed cleaning with a solvent.

4. Use the correct filler rod

One must carefully choose the filler rod for successful welding. Users must use filler rods depending on the base metals they are welding. For TIG welding, it is advantageous to utilize a thin metal filler rod to inject the weld metal into the weld puddle.

People also need to be very careful about the filler rod’s diameter. The general rule for determining the filler rod’s diameter is to choose a rod which has a lesser thickness than the plate you’re welding.

Fortunately, manufacturers provide users with charts to choose the right filler rod for various base metals.

5. Don’t melt the filler rod directly

One of the common mistakes that users do while welding is that they directly melt the filler rod in the welding arc. Never do it as the torch melts the base metal and the molten puddle melts the filler material.

Direct melting possesses the risk of contamination of the tungsten.

6. Adjust the appropriate flow rate & maintain travel speed

TIG welding involves using external shielding gas to safeguard the welds from the environment. Therefore, it is advantageous to utilize a flow meter to regulate the flow rate of gas on the gas bottle.

Extreme gas flow can cause disruption in the puddle while inadequate gas flow won’t be able to offer sufficient protection. Both extreme sides will contaminate the welding process.

So, maintaining the balance is vital for a better result. The main principle is to keep the flow meter between 20 cubic feet and 35 cubic feet per hour, then modify from there.

7. See the angle of the torch

The angle of the torch is crucial for TIG welding to determine the heat. The angle may vary based on the situation. However, some basic recommendations can help users to start with.

One can set the torch 90 degrees from the plate for butt joints. The travelling angle will be approximately 15 degrees in the way of travel. Filet welds require 45 degrees for even melting to the joint. However, you may require to adjust the angle based on the thickness of the metals.

8. Be comfortable

Users must simultaneously use their hands during TIG welding. But this simultaneous movement must be steady for a better result which is not easy to maintain.

Shaking hands will end up in a welding that looks incomplete and uneven. Furthermore, shaking hands can make significant differences in travel speeds. Therefore, one can follow the following tips for a smooth torch movement:

- Remain comfortable and maintain a good posture. One can rest the hands on an object for a better support.

- Avoid sudden changes in angle and travel speed. Keep the motion gradual and steady.

- Let the ceramic cup to contact with the metal. Therefore, you won’t need to hold it up in a vacant area. Ensure that the tungsten does not make any contact with the weld puddle.

- Always lightly drag your hands along with the weld.

9. Wear protective gear

TIG welding requires proper protective gear as Tungsten electrodes emit radiation. It will be wise to use TIG welding gloves instead of regular gloves. Regular gloves aim to safeguard skin from heat and sparks which is not that much necessary in TIG welding.

TIG gloves are lightweight and thinner than regular gloves. Therefore, you can easily move your hand. Always avoid using plastic gloves as they melt with heat.

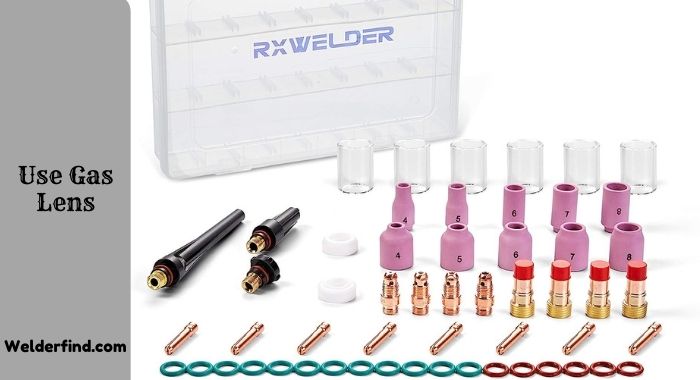

10. Use gas lens

A gas lens feature multiple layers of mesh screens through which the shielding gas flows. It results in an even and predictable shielding gas flow around the tungsten that generates higher-quality welds.

11. Start with minimum power

Extreme power can burn the weld. Therefore, it is always advantageous to use minimum power in order to produce a solid and strong weld.

12. Clean contaminated tip immediately:

The tip of the tungsten can become polluted at any stage of welding. So, it is vital to regrind the tip whenever they get contaminated. One of the common mistakes that beginners do is that they use excessive heat during welding.

The extreme heat breaks off the tip which later includes in the weld, contaminating the welding process.

However, maintaining a stable arc length and avoiding contact between the tungsten and the filler rod can prevent the tip’s contamination. Re-profile the tip whenever you will observe contamination in the tip or any change in the arc stability.

Final verdict

TIG welding is a difficult process that requires proper knowledge, practice, and expertise to do the job perfectly. Therefore, the beginner often fears to do TIG welding.

I have mentioned some of the most crucial TIG welding tips for beginners. I hope, these tips will make their TIG welding journey more comfortable and smooth.