Aluminum is a useful metal, we all know that. It is lightweight at the same time strong & that’s why the metal is a precious. We know there are aluminum’s of different thickness.

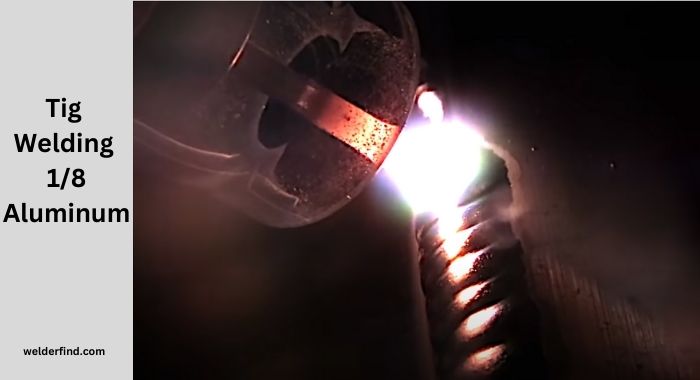

Today we will discuss about 1/8 inch aluminum and what settings you must configure your tig welder to weld it perfectly.

Can you Tig Weld 1/8 Inch Aluminum

Yes, it is possible to tig weld 1/8″ aluminum. You will need to consider the amperage range to do so. To weld aluminum most of the welders use 60-90 amp but to weld 1/8 inch you will need to increase the amperage. And you need a aluminum friendly tig welder for welding the sheet perfectly.

We have described the amperage requirement and speed of welding to weld 1/8 inch separately for different joints bellow.

Tig Welding 1/8″ Aluminum (But Joint)

In butt joint the following settings are used.

| Features | Settings |

|---|---|

| Tungsten | To tig weld 1/8 inch aluminum, 3/32″ diameter of tungsten is enough. You may use pure (green) or 2% ceriated tungsten in welding the aluminum sheet. You may use orange tungsten with inverter welder but you need to maintain 70% balance with frequency 100hz to avoid the split. |

| Torch Cup | Use water cooled cup |

| Filler Metal | 3/32″ or 1/8″ filler rod can be used |

| Amperage | You should use Ac current flow and 115-135 amp machine to weld the metal efficiently |

| Gas & Flow Rate | Argon gas is recommended in 17cft flow rate |

| Travel Speed | Start slowly and then increase the travel speed. Travel speed should not exceed 12 inch/minute |

Tig Welding 1/8 Inch Aluminum (Lap)

For lap joint, settings to tig welder is almost same to butt joint. Few variances in settings are required.

Lets find out them-

| Features | Settings |

|---|---|

| Tungsten | Same types of tungsten as butt joint |

| Torch Cup | 3/8″ Water cooled torch cup will be good. You may use 7/16″ also depending on the torch brand and requirement. |

| Filler Metal | Use 3/32″ filler metal |

| Amperage | Use amperage ranging from 105 to 130. Run the machine in AC mode. |

| Welding Speed | Speed should not exceed 10 inch per minute. That is move the torch slowly. |

Tig Welding 1/8Inch Aluminum (Corner)

For corner joint follow the settings bellow-

| Features | Settings |

|---|---|

| Tungsten | Same as butt and lap joint |

| Torch Cup | Follow the butt joint settings |

| Filler diameter | Same to lap joint |

| Amperage | Use 90-120 amp with Ac current flow |

| Gas & Flow rate | Gas flow rate should be 17cft and argon gas is enough |

| Speed | Speed of welding should be 12 inch per minute |

Tig Welding 1/8″ Aluminum (Fillet Joint)

| Features | Settings |

|---|---|

| Amperage | Use 100 to 140 amp for better weld. Don’t cross the limit. Otherwise base metal would crack |

| Speed | Speed of welding should not exceed 10/minute |

The settings we have discussed here, are for tig welding 1/8″ aluminum only. The settings may vary depending on the welder machine or aluminum condition. For example in case of aluminum and copper alloy settings maybe different than the above mentioned.

Moreover, 1/8 inch aluminum welding is not an easy task. You must be careful about travel speed, amperage and gas flow rate to maintain the stable weld. In some case tungsten can split or erosion can ruin the work. Therefor, you must ball the tungsten first and insert properly into the torch.

Most importantly, wear safety equipment’s before starting the welding. You may wonder why the same advice comes again and again, but it is crucial to avoid unfavorable state. So don’t compromise with safety.