TIG welding, which is also referred to as gas tungsten arc welding (GTAW), is a method that employs a non-consumable tungsten electrode to fuse metal pieces by generating an arc.

This process requires shielding gas, usually pure argon or a mixture of argon and helium. There are many kinds of TIG welding; however, Autogenous, Lift-arc, and Pulsed-arc are the most workable ones.

In this article, we want to take a look at how those work. Let’s dig into it!

Types of TIG Welding

There are three types of TIG Welding, which I will describe in detail below;

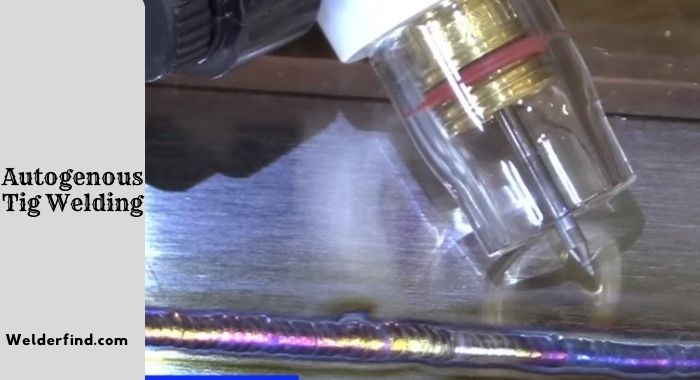

Autogenous

TIG welding without using filler material is known as autogenous welding. The welding process depends solely on the arc’s heat to melt the two joined pieces. This technique can be done using either direct current (DC) or alternating current (AC).

Autogenous welding is frequently used for thin materials such as sheet metal or aluminum tubing. It is also preferred for making accurate welds where excess material cannot be used.

Description and Ease of Use

Autogenous welding involves using the same composition for the base and filler materials. This technique can be utilized to create a weld by melting sections of the base metal without the need for an additional filler rod.

It is important to note that the term may have variations in its application.

Lift-arc

A lift TIG welder is a machine that uses the TIG welding process, which involves a non-consumable tungsten electrode to join metals by running a current through them.

This process is initiated through a light touch of the torch on the tungsten electrode to the metal, which is called a lift start. TIG welding, coupled with a lift start, has numerous advantages.

Description and Ease of Use

Arc welding is the process of using heat to melt metal and fuse it with electricity. When starting a TIG arc, there are three ways: scratch, lift, and high frequency. This method involves creating an electric arc between a metal electrode and the base material, causing them to melt and bond at the point of contact.

Pulsed Arc Welding

Pulse TIG welding is the way to go. By utilizing a foot pedal, this method allows for precise control. Additionally, the TIG torch generates a pulsating waveform, resulting in multiple waves in the final image.

Trust Pulse TIG welding to give you the accuracy and quality you need.

Description and Ease of Use

Pulse micro-arc welding is a process where an electrical arc is created between an electrode and the target component without any contact. The high energy density generated by the arc produces intense local heat that can be used for welding.

Which One is Easy?

As with any welding technique, practice, and experience are essential for improving welding proficiency. By starting with autogenous welding, beginners can build a strong foundation and gain confidence before venturing into more complex welding methods.

As skills develop and familiarity with TIG welding grows, welders can explore other techniques like lift-arc or pulsed arc welding to expand their capabilities and tackle more intricate welding tasks. So, if you are a beginner, then go for autogenous welding.

Conclusions

TIG welding is crucial for achieving optimal results in this specialized form of welding. Whether you are working with steel, aluminum, or other metals, selecting the appropriate tungsten electrode can greatly enhance the quality and efficiency of your welds.

From pure tungsten to thoriated and lanthanide tungsten, each type offers distinct advantages and considerations.

By considering factors such as material compatibility, amperage range, and overall longevity, welders can make informed decisions about which type of tungsten to use for their specific projects.

Great article! I found the information on the different types of TIG welding very helpful. As a beginner welder, I appreciate the suggestion to start with autogenous welding to build a strong foundation. I will definitely consider using pure tungsten for my specific projects based on the factors mentioned. Thank you for sharing your expertise! Rick Tillman

You are welcome. Keep reading and testing different tig welding types. Welding is really an amazing work.