Choosing a compatible and functional stick welding rod is necessary to sustain the welding arc and correctly add the essential filler metal to the weld joint.

But how do you pick the best stick welding rod from hundreds of options? To simplify your job, we have selected some top-quality rods from renowned brands.

| Products | Name | Description | Latest Price |

|---|---|---|---|

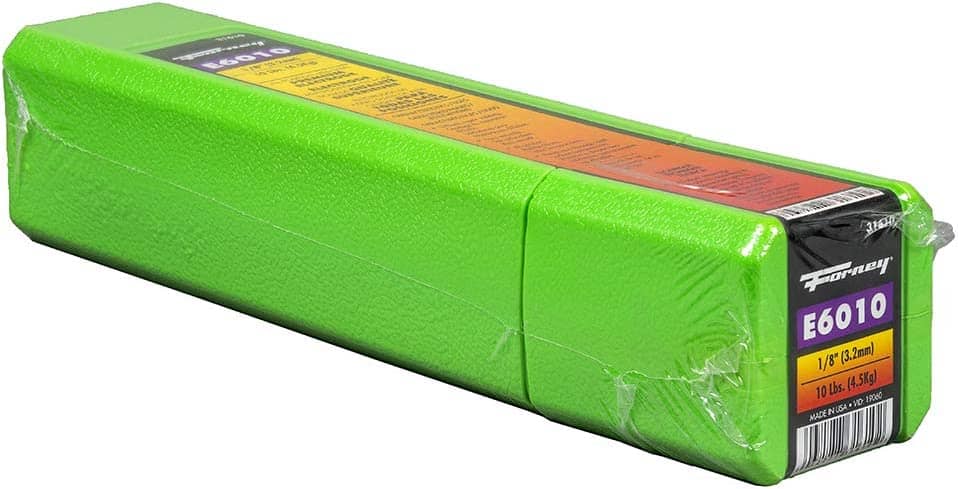

| Forney E6010 Stick Welding Rod | Material Mild Steel Grit Type Medium Compatible Material Carbon Item Weight 4.61 Pounds Grit Number 80 | Check Price Amazon |

| Blue Demon E6010 Stick Welding Rod | Brand Blue Demon Included Components Welding rod Item Weight 5 Pounds Blade Length 14 Inches | Check Price Amazon |

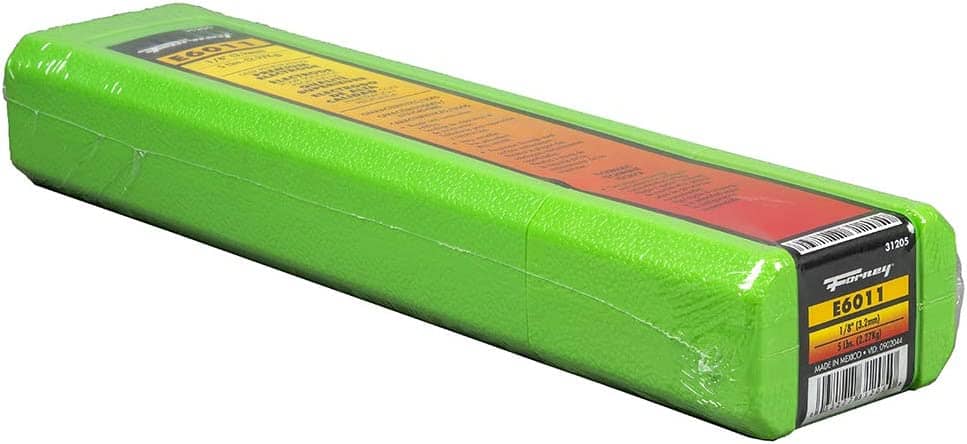

| Forney E6011 Stick Welding Rod | Current AC or DC Reverse Polarity Diameter 3/32”, 1/8”, 5/32” Amperage 30-80, 80-130, 120-180 Tensile Strength 60,000 PSI Tensile Strength | Check Price Amazon |

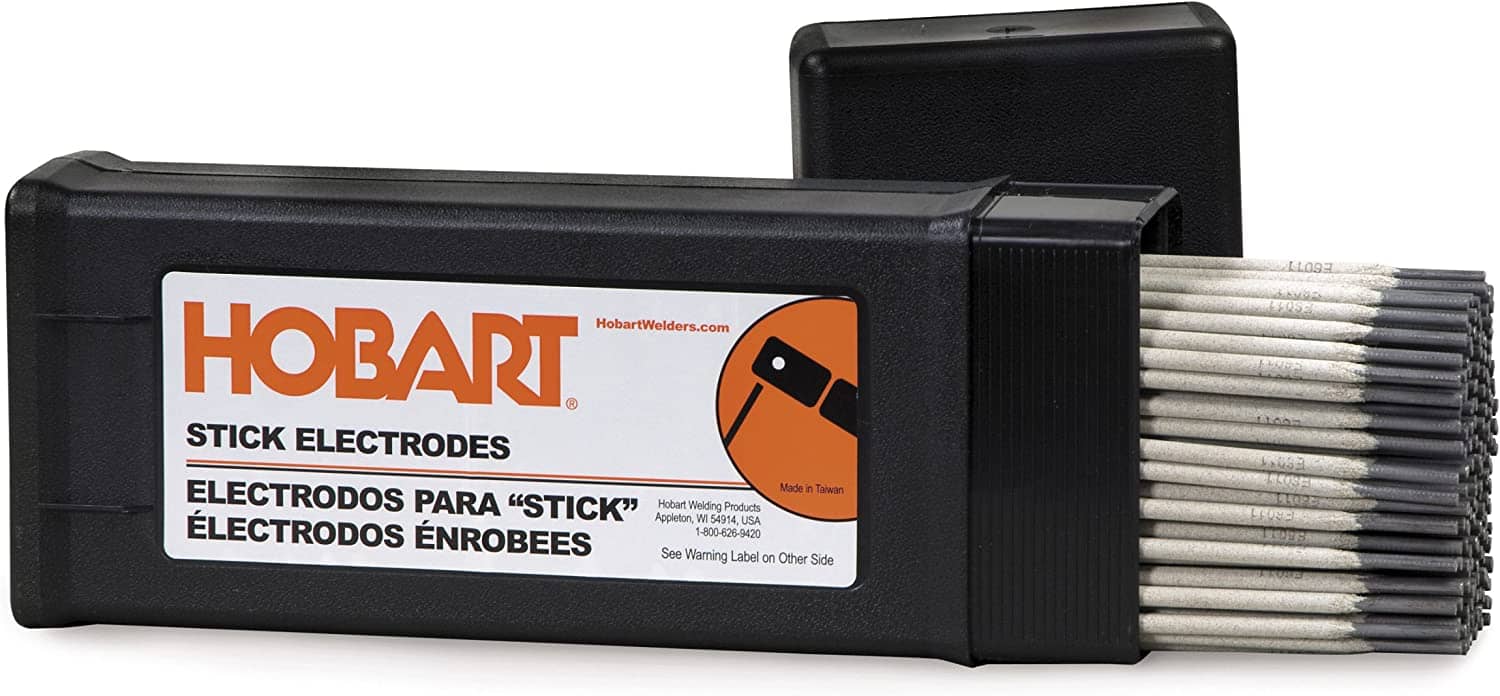

| Hobart E6011 Stick Welding Rod | Installation Method Arc-welding Size 1/8-10lbs Material Plastic Item Weight 10 pounds | Check Price Amazon |

| Weldcote E6011 Stick Welding Rod | Size 1/8 – 5 lbs – vacuum pack Material Cellulose coated Item Weight 5.15 pounds | Check Price Amazon |

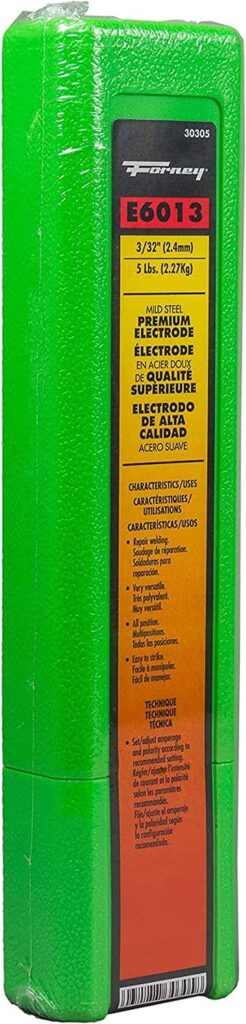

| Forney E6013 Stick Welding Rod | Size 3/32-Inch Style Rod Material Mild Steel Thickness 0.09 Inches Power Source AC/DC Capacity Description 60,000 tensile strength | Check Price Amazon | |

| KICKINGHORSE E6013 Welding Rod | Style 6013-3/32 Material Mild steel Power Source Ac_dc | Check Price Amazon |

| Forney E7018 Stick Welding Rod | Size 3/32-Inch Style Welding Rod Material Mild Steel Thickness 0.09 Inches Capacity Description 70,000 Tensile strength | Check Price Amazon |

| Hobart E7018 Stick Welding Rod | Size 1/8-10lbs Material Plastic Installation Method Arc-welding | Check Price Amazon |

| Blue Demon E7018 Stick Welding Rod | Size 3/32″(Diameter) Style 5# Plastic Power Source AC/DC | Check Price Amazon |

10 Best Stick Welding Rods

01. Forney E6010 Stick Welding Rod

Are you looking for stick welding rods for deep penetration? This Forney rod appears to be a perfect choice.

The welding electrode is suitable for weld galvanized steel and rusty/oily steel.

You can utilize this welding rod for various repair and maintenance tasks.

The unit makes a relatively smooth bead with a decent profile. You will see minimal porosity.

It is a highly versatile welding electrode in different positions, such as flat, horizontal, uphill, etc.

Pros

- A great welding rod for general-purpose fabrication, maintenance welding, etc

- Have a special coating to create a strong arc

- A low hydrogen content to prevent hydrogen-induced cracking

Cons

- Working in an overhead position could be better

Why Should One Buy This One?

If you are looking for a welding rod that can produce a high amount of metal deposition, this option appears perfect.

Why Is It Special?

The welding Electrode is suitable for dirty and rusty metal. It can help you create strong and clean welding after penetrating through the surface contaminants.

Check Forney E6010 Stick Welding Rod Price At Amazon

02. Blue Demon E6010 Stick Welding Rod

This welding rod is another versatile option. You can utilize the electrode in various positions, such as flat, horizontal, overhead, vertical-up, and vertical-down positions.

It has a blade length of 14 Inches, which is long enough for welding thicker materials or when deeper penetration is required.

However, don’t forget to use higher amperage to maintain a stable arc. You need to be also careful about spattering problems.

Pros

- High versatile to use the electrode in 5 to 6 different positions

- Comply with API (American Petroleum Institute) grade to o meet industry standards

- Comes with 5 pounds of rod in a single package to welding continuously for hours

Cons

- Rods are not the exact blue color shown in the advertisement

Why Should One Buy This One?

The API-grade welding electrodes are designed to produce high-quality welds with good penetration and minimal spatter.

Why Is It Special?

If you are searching for a reliable welding rod that provides good arc stability and is designed to produce minimal slag, look no further than this option.

Check Blue Demon E6010 Stick Welding Rod

03. Forney 6011 Stick Welding Rod

This Forney welding rod has Smooth arc wetting and spreads to keep the base metal and welding rod fused together properly.

Worry about porosity or lack of fusion? This versatile welding electrode is ideal for using all positions. It can significantly reduce the risk of welding defects.

Welders can use this welding rod in dirty, rusty, and painted materials where quick freezing and deep penetration are needed.

Pros

- Compatible to use with carbon steel, galvanized steel, and stainless steel

- Has good tensile strength to produce clean, smooth welds with minimal spatter

- Requires minimal preparation to save your welding time

Cons

- Some complained it creates a bit more smoke than others

Why Should One Buy This One?

This stick welding rod can keep a consistent connection or don’t lose ark. You can use it for less-than-ideal conditions due to its high cellulose content.

Why Is It Special?

One plus point of this welding electrode is providing decent control when welding in challenging positions or on thinner materials.

Check E6011 Stick Welding Rod Price At Amazon

04. Hobart 6011 Stick Welding Rod

This high-quality welding rod has a fast freezing slag that helps to hold the weld puddle in place.

Controlling the rod during the welding process is easier. Plus, it helps to minimize the risk of slag inclusions in the weld.

Besides, Hobart welding electrodes have 60,000 PSI tensile strength. It comes in handy for high-stress applications, such as structural steel, heavy equipment, and pipelines.

Plus, it provides higher resistance to strain and stress. This decreases the risk of weld failure under heavy loads or pressure.

Pros

- A perfect choice for welding applications that require high strength and reliability

- It can burn through contaminants more quickly than some other types of welding rods

- Comes with good packaging to keep all rods safe inside the bag

Cons

- Some complained the arch occasionally failed in the middle of the welding

Why Should One Buy This One?

This high-quality stick welding rod is perfect for welding in any position. It will reduce downtime and increase productivity as you don’t need to change the rod.

Why Is It Special?

This welding rod can run more smoothly, especially if you have an AC-only machine. It will work well even on rusty metal and produce deep penetration.

Check Hobart E6011 Stick Welding Rod

05. Weldcote E6011 Stick Welding Rod

Are you fed up with too much fume production during the welding process? This welding rod can reduce the welding smoke by up to 60%.

It can ensure minimal defects like porosity, undercutting, and slag inclusion.

You will achieve a smooth and uniform weld bead as the rod will melt at a consistent rate.

Besides, the welding electrode can maintain a consistent arc length and travel speed. You will achieve greater precision and accuracy in the weld.

Plus, the Weldcote rod requires less heat input. It will decrease the risk of heat distortion or warping of the base material.

Pros

- Offers easy slag detachability to add a clean and aesthetically pleasing appearance

- Decreases the time and effort required for post-weld cleaning

- Reduce the risk of moisture and corrosion buildup

Cons

- Sounds slightly different than my regular rods

Why Should One Buy This One?

This welding rod is a perfect addition if you prefer a consistent and smooth arch. It can offer penetration with minimal smoke.

Why Is It Special?

The welding electrode will provide the same mechanical properties as the base metals being joined. It also has an increased micro-hardness and tensile strength.

Check Weldcote Stick Welding Rod Price At Amazon

06. Forney E6013 Stick Welding Rod

Are you looking for a reliable welding rod for shallow penetration?

This high-quality welding electrode is designed to create a medium-penetrating weld bead.

It is made of mild steel. Plus, the unit has a layer of flux coating to protect the weld from contamination and provide a shielding gas.

You can use this option for welding thin metals or metals with low melting points

Welders don’t have to worry about excessive heat and penetration that would cause distortion or burn-through.

Besides, you can utilize the welding rod in poor fit-up conditions because it has a strong arc and can tolerate a greater degree of variance

Pros

- Impressive wetting action to improve the fusion between the base metal and the weld metal

- Decreases the risk of porosity, incomplete penetration, and other failures

- A fast-freezing slag system to produce smooth and flat weld beads

Cons

- No instructions on outside how to open

Why Should One Buy This One?

If you want to produce a medium-penetrating weld with minimal burn-through or distortion, this option is perfect.

Why Is It Special?

The sticking welding electrode produces a relatively low spatter. It will significantly decrease cleanup time and improve the appearance of the finished weld.

Check Forney E6013 Stick Welding Rod Price At Amazon

07. Kicking Horse E6013 Stick Welding Rod

This stick welding rod is relatively easy to control, even for beginners or DIY enthusiasts.

You can achieve a consistent and uniform weld bead, contributing to a good overall appearance.

Besides, This Kicking Horse welding electrode creates low-volume, fast-freezing, and non-stick slag.

Removing the slag is easygoing as it will not adhere to the weld bead or the surrounding material.

Welders can utilize a hammer and chisel to chip off the slag. No need to use any special tool!

However, follow proper welding procedures and techniques to get the best results.

Pros

- Easy to control the heat input and reduces the risk of burn-through or distortion

- A good choice for DIY enthusiasts or beginners, especially for the first time

- Decreases the requirement of post-weld cleanup

Cons

- Sensitive to surface contamination, such as oil or rust

Why Should One Buy This One?

If you are looking for a special welding rod for sheet metal applications, this option is the best one as it has a relatively low penetration depth

Why Is It Special?

This welding electrode decreases the amount of material that needs to be ground or sanded down after the weld is completed.

Check KIkinghorse Stick Welding Rod Price At Amazon

08. Forney E7018 Stick Welding Rod

Are you searching for a welding rod to weld high-strength, low-alloy (HSLA) steels?

If so, this option is an excellent choice. You can utilize this welding electrode where high strength and toughness are required.

Besides, it has a low hydrogen content, which helps to prevent hydrogen-induced cracking (HIC) in the weld.

In addition, the Forney welding rod is an excellent choice for welding hard-to-weld steels.

It can produce welds with a high tensile strength that may be subjected to high stress or impact.

Also, welders can utilize the rod for minor and temporary welds to keep components together and ready for final welding.

Pros

- Perfect for using out-of-position welding with proper adjustment

- Well-suited for welding cold rolled steel to achieve a high degree of precision and surface finish

- Equipped with a low-hydrogen iron coating to avoid cracking issues

Cons

- Not the best choice if you have a lot of tacking to do

Why Should One Buy This One?

If you are looking for a versatile welding rod with both AC and DC welding machines, this option is perfect for welding in different environments.

Why Is It Special?

Welders can utilize this welding electrode to produce a smooth, even appearance where aesthetics are essential.

Check Forney E7018 Stick Welding Rod Price At Amazon

09. Hobart E7018 Stick Welding Rod

This welding rod allows welders to weld with a high tensile strength of 70,000 PSI

It can ensure stronger welds where the welded joint is subject to high stress or load. The welding result will be more durable and resistant to wear and tear.

Moreover, you can utilize this versatile welding electrode on low, medium, and high-carbon steels while minimizing the potential hazards associated with welding.

Plus, it is a low-hydrogen electrode, making it an ideal choice for crack-sensitive applications. The rod will decrease the risk of hydrogen-induced cracking.

Pros

- Easy to avoid hydrogen entrapment in the weld metal and prevent cracking issues

- Simple to weld with a higher tensile strength to achieve increased deposition efficiency

- Produces welds with less spatter and better bead appearance

Cons

- Not the best choice for beginner welders

Why Should One Buy This One?

If you are looking for a highly flexible sticking rod that can be used on high-strength, low-alloy, and stainless steels, this option appears to be a perfect choice.

Why Is It Special?

This Hobart stick welding electrode can provide greater flexibility and safety in welding applications and help ensure that the welded joint can withstand high stress or load.

Check Hobart E7018 Stick Welding Rod Price At Amazon

10. Blue Demon E7018 Stick Welding Rod

Are you looking for a particular welding rod for medium-grade carbons steels? If so, look nowhere than the Blue demon welding electrode.

This welding rod can produce welds with good impact properties. You can use the option where the welded joint may be subjected to shock or vibration.

The welding electrode is well-suited for low-alloy structural as it provides stronger joints.

Besides, welders can produce welds while holding the electrode in any position. It will cause minimal spatter while ensuring a smooth and consistent puddle flow.

Pros

- Effortless to strike and release the slag for precise refining and joining of the welding metal

- Doesn’t require any preheating to avoid discoloration and oxidation on the base metal

- Not prone to change the metallurgical structure of the base metal

Cons

- Slag is thicker and a bit difficult to remove

Why Should One Buy This One?

Welders who want to weld low-alloy structural, low, medium, and high-carbon steels can use this option to achieve high-quality welding results.

Why Is It Special?

This stick welding rod doesn’t require any preheating. It will reduce the risk of distortion and less material waste. Also, you will achieve a more uniform appearance.

Check Blue Demon E7018 Stick Welding Rod Price At Amazon

What Rod/Electrode Can You Use In Stick Welding?

Welders can your various types of rods or electrodes in stick welding.

But 6010, 6011, 6013, 7018, and 7024 are the most widely used options.

Their diameter ranges from 1/8- to 5/32 inches.

Before choosing a particular rod, make sure it matches the strength properties and composition of the base metal.

Significance Of Number On The Electrode

Welding stick Electrodes are different ratings. Their suitability varies.

The following table shows various welding electrodes and their ideal usage.

| Rod Number | Ideal usage purpose |

| E6010 Welding Electrode | Pipeline welding |

| E6011 Welding Electrode | Mild steel, galvanized steel, and some low alloy steels |

| E6013Welding Electrode | Thin metals and light to medium fabrication work |

| E7018Welding Electrode | High-strength steel |

Significance Of Size Of Electrode

Stick rods are available in different sizes.

The following table shows various sizes of stick rods and when you should use them.

| Rod Number | Ideal usage purpose |

| 1/16 in. (1.6 mm) | Sheet metal or thin-wall tubing |

| 3/32 in. (2.4 mm) | Steel plates and structural steel |

| 1/8 in. (3.2 mm) | General fabrication and repair work |

| 5/32 in. (4.0 mm) | Thick plates and large structural steel components |

| 3/16 in. (4.8 mm) | Heavy machinery and bridge construction, |

Buying Factors For Selecting the Right Electrode

Choosing the right stick welding rod is crucial for producing high-quality welds.

The following factors can help you determine the best stick welding rod to use based on your welding application:

01. Penetration

Penetration is the depth to which the welding rod can penetrate the base metal.

If deep penetration is required, an electrode with a high current capacity should be used.

Electrodes with a low current capacity are used for shallow penetration.

02. Welding Position

The position in which the welding will be done is another important factor.

Some welding positions, such as overhead or vertical, require electrodes with a special coating.

It provides a stable arc and prevents the molten metal from falling.

03. Tensile strength

The tensile strength of the welding rod determines how strong the weld will be.

Choose a welding rod with high tensile strength if you need a strong weld.

04. Material

The material being welded will also determine the type of electrode to use.

Different types of electrodes are designed for specific materials, such as steel, cast iron, or aluminum.

05. Size

The diameter of the electrode is another essential factor to consider.

Larger diameter electrodes are used for thicker materials, while smaller diameter electrodes are used for thinner materials.

06. Thickness

The thickness of the material being welded will also determine the type of electrode to use.

Thicker materials require a higher amperage and larger electrodes.

07. Current

The current required for the welding process will also determine the type of electrode to use.

High-current electrodes are used for thicker materials and vice versa.

Frequently Asked Questions

How do I identify a Stick welding rod?

Identifying a stick welding rod requires checking the rod’s base area to where 4-5 digit alphanumerical code is written.

What is the easiest stick welding rod?

E6010 is the easiest stick welding rod, offering a quick-starting, steady, and penetrating arc. Plus, this fast-freeze electrode can produce a deep penetration arc.

Wrapping UP

Selecting the best stick welding rod depends on the type of material you are welding, the welding position, and your level of experience.

E6013 is often recommended for beginners due to its forgiving nature, while E6010 is better for thicker materials and more advanced welders.

It’s important to choose the appropriate electrode for your specific job and follow the manufacturer’s recommended procedures for use.