If we look closely, there is the use of stainless steel everywhere. Wherever stainless steel is used, welding is used to attach different pieces.

Do you know that different types of stainless steel require other welding rods to weld ideally? If your welding rod selection is wrong, you won’t get the desired welding result.

So, today I’ll discuss stainless steel with some recommendations for the best welding rod for stainless steel

So, without wasting any time, let’s begin

| Product | Name | Description | Price |

|---|---|---|---|

| WeldingCity Stainless Steel 308 TIG Welding Rod | Product Dimensions 36 x 3 x 3 inches Material Stainless steel Size 5-Lb 3/32″ Shape Tube | Check Price |

| ER308L stainless steel TIG welding rods | Size 1-Lb 1/16″ | Check Price |

| Blue Demon E308 Plastic Stainless Steel Arc Welding Electrode | Product Dimensions 14 x 3 x 3 inches Size 1/8″ Item Weight 5.21 pounds | Check Price |

| Forney 44557 Stainless Steel Specialty Rod | Item Dimensions LxWxH 1 x 15 x 1 inches Material Stainless Alloy Brand Forney Thickness 0.09 Inches Item Weight 1 Pounds | Check Price |

| KUNWU Stainless Steel TIG Welding Rods | Product Dimensions 36 x 0.1 x 0.1 inches Material Stainless Steel Shape Straight Size 3/32″ | Check Price |

WeldingCity Tig Welding Rod ER308L

Welding city is not an unfamiliar name if you have been in the welding industry long enough.

Now, if you are looking for one of the best welding rods this manufacturer has, it’s their R308L Stainless Steel 308 TIG Welding Rod.

First, these welding rods are available in wide diameters and sizes. Do you know what that means? No matter how versatile your projects or your needs are, you’ll always get it done from this variety of options.

There are several weight packages if you want to test these rods and buy more later.

Moving on to the compatibility, You can comfortably weld the most common types of steel, including 304, 304L, 308, 308L, 321 and 347.

Another thing these rods are compatible with is argon gas? So, what does that bring to the table? You get the most stable arc possible with a clean weld.

Good side

- Compatible with different types of stainless steel

- Sold in different sizes and diameters

- You get to pick the size pack you want

- Generates clean and stable arced weld

- Excellent for use in cryogenic temperature

Bad sides

- The packing can use improvement

- Not a good fit for corroded stainless steel

Why should one buy this one?

The main selling point of these welding rods is their balance. It has everything like durability, variation and, most importantly, performance to give you the best stainless steel welding result.

Why it is special

The versatility these welding rods offer makes them separate from the rest. Whether you are a professional or beginner, using these with different rods makes these rods an easy recommendation.

ER308L Stainless Steel Tig Welding Rods

The manufacturer might not be familiar this time, but this rod’s performance will make you come back for more. These welding rods are made with the highest quality stainless steel to support any welding project you want.

As long as you are using these rods for lighter projects, you should be absolutely fine. Especially if you consider the rice, it’s an easy recommendation for DIYers and beginners.

The welding experience was pretty consistent, so you can expect a clean and well-distributed weld when you finish. There is a slight catch as you need to clean the weld to avoid glue residue, but given other features, you should give it a pass.

Good Side

- Consistent welding experience for any project

- Made of the highest quality stainless steel

- Usable in any welding position

- Compatible with various types of stainless steel

Bad Side

- You’ll need to clean up after the welding is complete

- These rods don’t come in a tube

Why should one buy this on

These stainless steel rods offer great value for money options to get some essential work done, such as food-grade projects.

Why it is special

The consistency of these welding rods is commendable. You can easily compare with the higher price and more premium options on the mart.

Blue Demon Stainless Steel Arc Welding Electrode

Blue Demon doesn’t need any introduction when it comes to welding rods. Whether you want clean welding, consistency or the perfect arc, their E308L welding rods are here to suffice your need.

These welding rods greatly benefit you if you are looking for mid to deep penetration. As the rods are marked compatible with AC-DCEP current, it’s easy to get the penetration right consistently with a softer arc.

Another great feature you’ll love is the very low carbon composition of .045. As a result, there will be a minimum formation of chromium carbide. The rods are easy to strike, which is an advantage for beginners.

However, keep in mind that the rods run pretty slow. So, if you are comfortable with a faster travel speed, you might have poor welding results.

Good Side

- You can quickly strike the arc

- Slow running rods ensure longevity

- The slags are removable easily

- Easy to use with consistent bead

Bad Side

- The packing needs improvement

- Not a good fit for thinner metal

Why should one buy this one

On the right hand, Blue Demon E308L can be the perfect welding rod for home projects. These rods are remarkably consistent and accessible to start the arc, giving it an upper hand for beginners.

Why it is special

These attributes make this Blue Demon welding rod pack special with outstanding build quality, excellent control, and zero spatters.

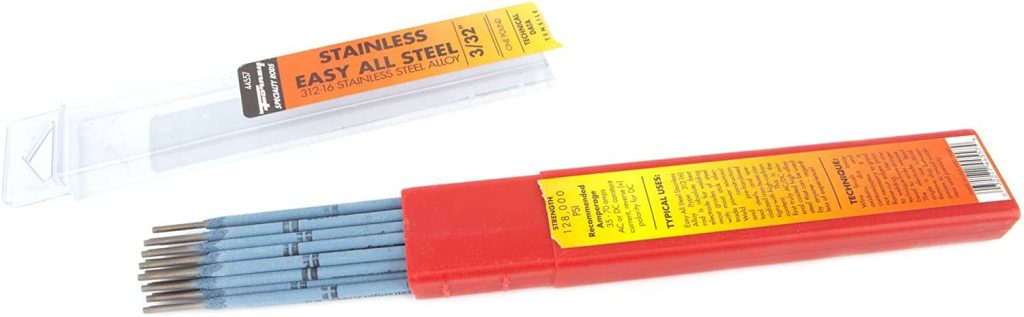

Forney Stainless Steel Welding Rod

The previous rods I discussed were better suited for MIG and TIG welding. But if you are willing to stick weld stainless steel, these Forney 4457 are here to make your job easier.

First of all, the tensile strength of these rods is outstanding, with 128000 PSI. So, no matter how much abuse you put the weld through, it’ll hold up.

No matter the voltage of your welder, you can run these rods at both 120 and 240 volts. That means more welders can get these rods without worrying about the amperage control.

These rods are pricier than their competitors, but they also make up for that fact with an easy and consistent bid. Also, there is some slag generation, which is also hard to remove.

Good Side

- Particularly convenient for stick welding

- Excellent tensile strength for added durability

- Works great with both 120V and 240V

- One of the easiest to start an arc

Bad Side

- Pricier than the competitor welding rods

Why should one buy this one

As per my experience, this is one of the easiest rods to start an arc. The price might not make it a good choice for regular use. But for practice and learning, these Forney welding rods are one of the best.

Why it is special

The specialty of this Forney welding rod is made of 312-16 stainless steel alloy. This alloy makes these welding rods eligible for multiple grades of stainless steel with any power source.

KUNWU Stainless Steel Tig Welding Rods

The last option I have brought for you is from KUNWU. If your jobs involve welding austenitic stainless steel like 304L, 308L, 321 and 347, these welding rods have the perfect features. The higher chromium and nickel content makes the welding rods particularly easy to weld.

One thing I would like to add here is that these welding rods are also usable for welding kitchenware, food applications and general purpose.

In all of these sectors, corrosion resistance is a significant factor. So, KUNWU got rid of that issue by having a low carbon content of only 0.03%.

Welders often have concerns about the packaging of welding rods due to moisture contamination. So, KUNWU took care of that by using PVC tube packaging to store the rods.

Good Side

- Compatible with different grades of stainless steel

- Excellent for use in the food industry and kitchenware

- It comes in improved packaging

- Lower carbon content to prevent corrosion

- Great value for money

Bad Side

- It takes time to clean the slag afterwards

Why should one buy this one

KUNWU stainless steel welding rods offer the highest quality, reliability and consistent performance at a very reasonable price.

Why it is special

The versatility of working with different grades of stainless steel is the specialty of KUNWU TIG welding rods. For the same reason, you can buy these welding rods as a multipurpose welding option.

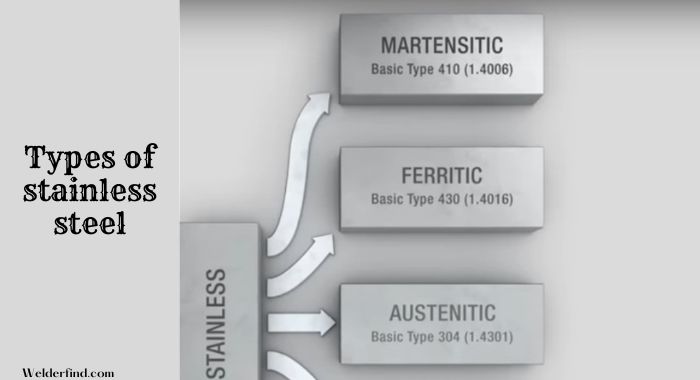

Types Of Stainless Steel

Before we get to the welding rods, you must familiarize yourself with the varieties of stainless steel available on the market. Though some common features are standard in every stainless steel, they differ in usage and other attributes.

So here is a short introduction to different types of steel.

Austenitic stainless steel

First, we have the austenitic stainless steel, the most common one of the bunch. Also, austenitic steel has the highest chromium ratio, making it more corrosion-resistant and nonmagnetic.

In addition, this type of stainless steel is known for its weldability and is therefore used for domestic use—architectural and transport projects.

Ferritic Stainless Steel

Then we have the ferritic steel, with a little less chromium and nickel content than the previous austenitic steel. Unlike austenitic steel, ferritic stainless steel is magnetic, and you can harden it by cold working.

Ferritic stainless steel is mainly used for kitchenware and automotive parts.

Martensitic Stainless Steel

The least common type of stainless steel is martensitic. It has lots of similarities to ferritic steel in terms of composition.

However, the carbon content in martensitic is much higher. Therefore it can be hardened quickly. This type of steel is used for knives and surgical instruments.

Which process is suitable for Welding Stainless Steel

Now that you know about the stainless steel variants let’s look at the options you can use to weld stainless steel.

Here is a little discussion about the standard welding process and its compatibility with stainless steel.

TIG

Primarily, TIG welding is considered stainless steel’s most ideal welding process. This process is used with shield gas like argon or argon mixed with other gas. TIG welding might be slow and expensive, but it’ll produce the best quality weld possible.

MIG

MIG welding is another reliable and widely used welding process for stainless steel. If you prefer durability, you can try welding MIG with stainless steel.

It’s also time and cost-efficient, but remember, it can ruin the tidiness.

Stick

You can use the stick welding method too for stainless steel. However, there is some catch. First, you’ll need the correct electrode, ideally a 308, 309, 310 or 312 SMAW. Each of them differs in price and joint quality.

Stick welding for stainless steel is mainly used for repair and maintenance projects.

Can you weld stainless steel with regular rods?

Every material has a compatible welding rod. Keeping this in mind, you cannot weld stainless steel with regular welding rods used in MIG or TIG welding made of materials other than stainless steel.

What type of welding rod is used for stainless steel?

Typically, only the graded welding rods are the best suited for welding stainless steel. More specifically, various grades of stainless steel and different welding rods are available to weld stainless steel.

Welding rods for different grade

Earlier I mentioned various grades of stainless steel. Instead of explaining these grades, I am discussing a few grades and their welding rods.

304: Let’s talk about 304 steel first. 3034-grade stainless steel falls under the austenitic category. As mentioned earlier, it has a higher chromium and nickel content of 16-26% and 8-22%, respectively.

This grade of stainless steel is weldable with 308 welding rods.

316: This is another stainless steel grade primarily used in the food industry in related applications. Whether it’s cutlery or kitchenware, 316 stainless steel is the ideal choice, and they are welded by 316 welding rods.

430: Next, we have 430 stainless steel, an option from the ferritic stainless steel group. As a general characteristic of ferritic steel, it has lower chromium and carbon content than 304 or 316-grade steel.

Therefore, 430 electrodes are used for welding this grade of steel.

434: Another ferritic stainless steel with wide usage across different industries. This stainless steel has extra molybdenum that increases the corrosion resistance. Like the previous grades, there are 434 welding rods available to weld 434 stainless steel.

Stainless steel welding rod buying guide

Welding might be complicated, but you can make it easier by selecting a suitable welding rod for your project. Here are some factors you should consider while purchasing a stainless steel welding rod.

Tensile strength

If you want your weld last long, you need to check out the tensile strength of the welding rod. The minimum threshold here is to match the tensile strength of the welding rod with the base material.

You can avoid cracking and welding without damaging the base material. Usually, the first two digits of the AWS classification refer to the tensile strength.

Current

Next, check the current source to weld with that particular welding rod. A special welding rod can only weld either with AC or DC. Additionally, some welding rods can work with both types of currents.

You should go for AC-compatible welding rods if your goal is deep penetration. The fourth digit of AWS classification refers to the current compatibility.

Base metal thickness

Just considering the welding rod features isn’t enough. Sometimes, you’ll also need to consider the thickness of the base material. The thickness will decide what type of welding rod can do the job.

If the base material is thick, you need higher flexibility and low hydrogen content welding rod. On the other hand, if the base material is thin, get a welding rod with a small diameter and soft arc

Last words

That’s a wrap for today. I hope my article was helpful enough to give you an idea about different types of stainless steel and comparable welding rods.

Welding stainless steel will be much easier now that you have the direction to the suitable welding rods.

FAQ

Can you use 7018 on stainless?

7018 welding rods are primarily used for medium carbon, high carbon and low alloy steel. Unfortunately, stainless steel is none, and using 7018 on stainless steel can result in poor welding results with no strength and corrosion resistance.

Can I weld stainless steel with a stick welder?

Yes, you can weld stainless steel with a stick welder. Though stick welding stainless steel is not an ideal process, using the right electrode can bring decent results to repair and maintenance welding jobs.

Hi, it’s Ed again, i’m 87 and after 60 years at welding, still learning go tips from your info today.