Stick welding galvanized steel, also known as cold galvanization, is a common, cost-effective, versatile process used in industrial applications to join galvanized steel.

But you will have to use the best stick welding rod, know every step of stick welding, and find solutions to common mistakes.

Can Galvanized Steel Be Welded With A Stick Welder?

Yes. Galvanized steel can be welded using a stick welder. It uses a metal electrode that is coated with flux. You will have to use an electrode that is recommended for galvanized steel.

You must preheat the metal before welding to prevent zinc oxide from forming. It will reduce the cooling rate of the metal and won’t allow it to crack.

A low amperage setting is also crucial for stick welding galvanized steel. It won’t melt down the zinc coating.

So, you can weld galvanized steel with a stick welder, but you will have to use the proper techniques with the right tools.

What Are The Best Stick Welding Rods For Galvanized Steel?

Choosing suitable welding rods or electrodes is crucial for stick welding galvanized steel. A wrong rod can hamper your welding process and damage the steel in many ways.

So, let’s see some of the best stick welding rods for galvanized steel:

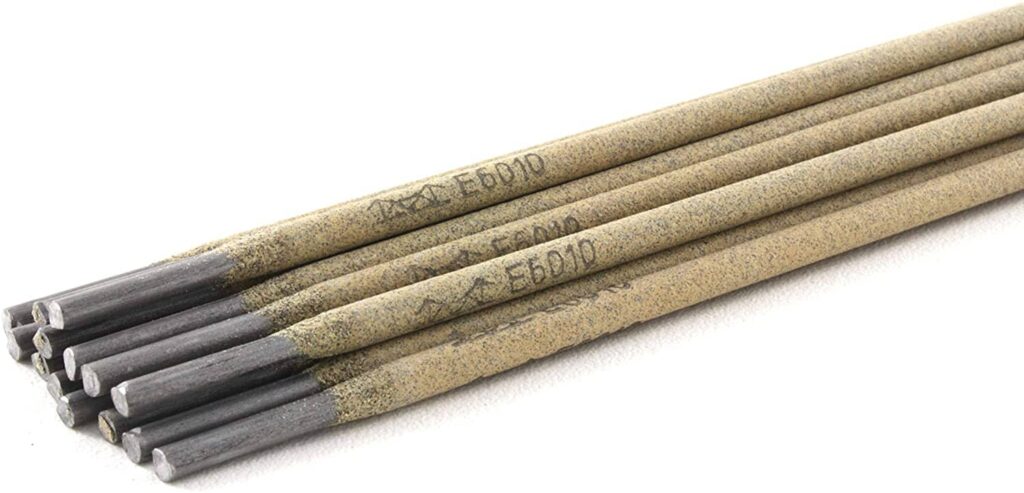

E6010

E6010 stick welding rod comes with a deep penetrating arc capable of penetrating through the zinc layer of the galvanized steel.

It’s a DC-powered, all-position, low-hydrogen rod designed to weld galvanized steel.

E6011

E6011 is a low-hydrogen and all-position rod used in welding galvanized steel. You can use it with both AC and DC power.

Using this stick welding rod, you can weld galvanized steel in various positions, such as vertically up and down. Besides, it also allows out-of-position welding.

E7018

E7018 is also an all-position stick welding rod that runs on AC and DC power. It has a potassium and iron power coating with low-level hydrogen.

The slow freezing puddle of this electrode rod makes it a great choice for welding galvanized steel by creating a thick slag.

How To Stick Weld Galvanized Steel

There is a well-defined process for stick welding galvanized steel. You must know the process ins and out to get the best result. Here is the process of stick welding galvanized steel in 7 steps:

Step 1: Collect All the Ingredients

Firstly, you must gather all the necessary ingredients for the job. Invest in safety equipment, such as helmets, gloves, goggles, face masks, etc., to protect your face and eyes from sparks and splatters. Make sure all the equipment is at your arm’s length during welding.

Step 2: Clean the Galvanized Steel

You have to clean the galvanized steel before stick welding. Zinc coating in galvanized steel is already tricky to cast; dust, grime, or oil can make it even worse.

So, you will have to clean the steel, especially the joint, with a wire brush or sandpaper.

Step 3: Select the Right Rod for Stick Welding

Zinc coating on galvanized steel requires some consideration during stick welding. You have to select the right rod for the process.

You can choose a rod from the above as they are the best for this purpose. You have to select the right rod size based on your metal’s thickness and join type.

Step 4: Make the Joint Ready and Clamp the Metal

Now, you have to prepare the joint and clamp the galvanized for welding. The process is similar to uncoated steel, with some exceptions.

For the butt joint, you have to keep a wider root gap for zinc to escape easily. Some other joints, such as tee fillet and lap, are difficult without removing the zinc coating.

Step 5: Set Up the Correct Amperage

You have to set up the correct amperage for the stick-welding galvanized steel. 5% amperage is the right amount as it can burn zinc coating properly.

However, you will have to increase the amperage for filet welding.

Step 6: Stick Welding Galvanized Steel

Finally, it’s time to stick-weld your galvanized steel. Try to go slow and steady. Reduce your speed to 80% to make the process easier.

Using a wide rod manipulation will help you reduce the speed. Use a flame torch because it cools down the workpiece faster.

Step 7: Restore Galvanization

After stick welding, you should restore the corrosion-resistant capability of the workpiece. You may find some new pellets and burnt galvanization around the joint. Crush them with a grit flap and then rub them with a clean cloth.

Finally, spray zinc-infused paint on the exposed areas.

What To Focus When Stick Welding Galvanized Steel

For stick welding galvanized steel, you must take special precautions because galvanized steel produces toxic fumes. Let’s see what you should focus on during the process:

- Use a low-hydrogen welding rod to reduce heat.

- Try to remove the zinc coating from the surface.

- Use protective gear, especially a welding hood and a respirator.

- Restore galvanize to protect the workpiece from rusting.

- Try to maintain the best stick welding practices.

Stick Welding galvanized Steel Common Mistake & How Avoid Them

Now, let’s check out some common mistakes people make during stick welding galvanized steel and ways to avoid them:

Keep Rod Attached to the Metal

Most beginners make this mistake. You should unclamp the rod from the workpiece manually when they are attached.

Otherwise, it will turn your metal orange. So, make sure the amperage is correct according to your metal.

Not Cleaning the Work Area

Make sure to clean your galvanized metal before welding, as dirt, soil, oil, etc., can make welding difficult.

Not Having Proper Ventilation

Always ensure proper ventilation in the workplace because toxic fumes can cause health hazards.

Last Words

In conclusion, stick welding galvanized steel is a complex process, and you should be very careful at every step.

If done correctly, you will get strong and durable welding of galvanized steel using this process. So, make sure to follow the best practices with the proper techniques.

FAQs

What are the dangers of welding galvanized steel?

Welding galvanized steel has several dangerous and harmful aspects, including toxic fumes. It can harm your respiratory system along with the lung.

How do you protect galvanized steel after welding?

You should re-galvanize your workpiece after welding to protect it from rusting. A zinc-rich paint can do the job.