Tig welding thin metal is not an easy task especially in case of aluminum. You may burn-through the metal easily. 1/16 inch aluminum is thinner and you must set your tig machine and other accessories to comply with the application.

We will discuss the correct settings of your tig welder to weld 1/16 inch aluminum alloy.

Types of joint

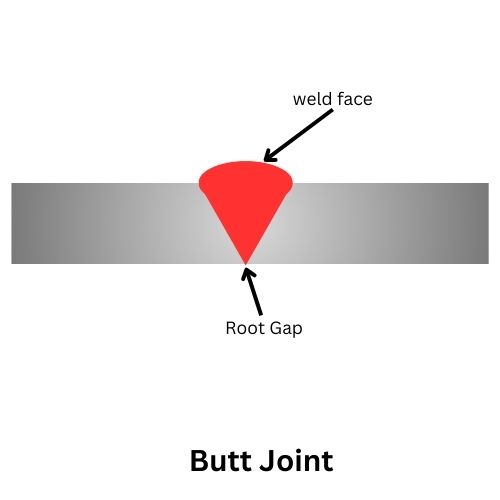

- Butt Joint

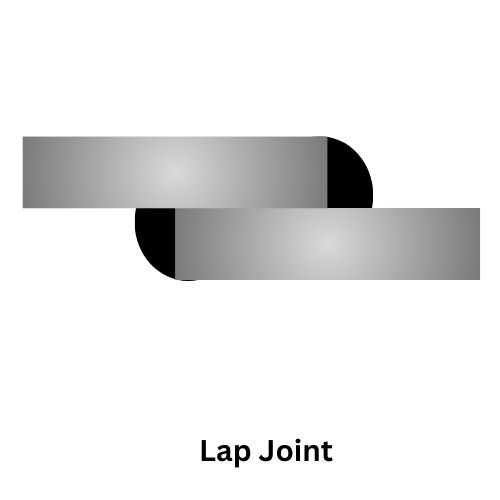

- Lap Joint

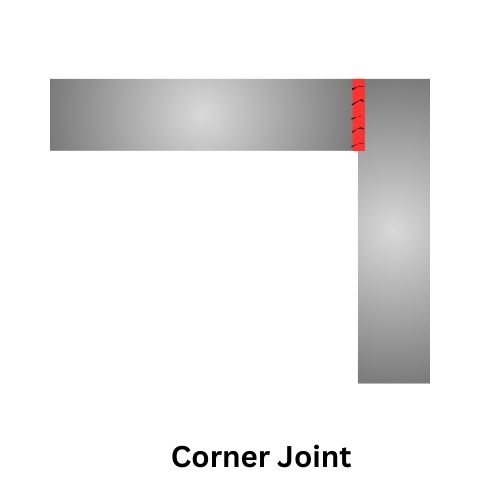

- Corner Joint

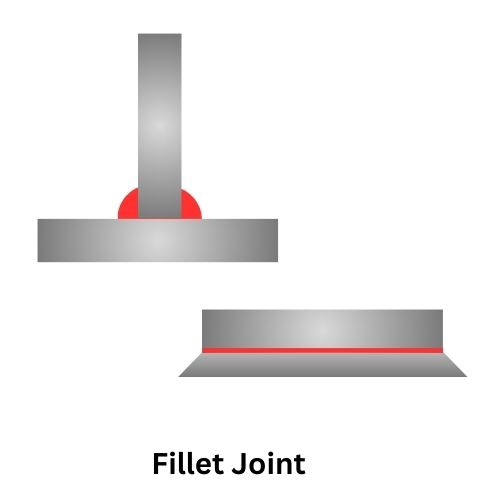

- Fillet Joint

We will discuss the settings of tig welder for each joint.

Butt Joint

It is simple form of welding joint where two pieces of work metal is placed side by side and welded along the join area.

To butt weld 1/16″ aluminum follow the settings bellow-

| Feature | Settings |

|---|---|

| Tungsten Diameter | Use pure tungsten (green) for butt welding 1/16 inch aluminum. You may also use 2% ceriated (grey) tungsten. For inverted tig welder weld with 2% ceriated tungsten at 100hz frequency for best result |

| Torch Cup | Use water cooled torch (1/4-3/8″) if you are using more than 250amp welder and may use ceramic cup torch for welder under 200amp. |

| Filler Metal | Filler metal you should use is 1/16 inch or 1.6mm. |

| Polarity | Ac tig would be better for butt welding 1/16 aluminum |

| Amperage | Ranges from 65 to 75 amps |

| Gas | Argon is better for butt welding 1/16 aluminum but for thicker metal combination of argon and helium would be best. Set the gas flow rate at 15cft. |

| Travel Speed | You should be slow at the beginning of welding then slowly you may increase the speed. We recommend to weld 12inch/minute. |

| Position | Flat, Horizontal and Vertical |

Lap Joint

Lap joint is basically placing two pieces of metal in overlapping style and weld to join them together. Normally used in joining two different types metal.

To lap weld 1/16″ aluminum follow the settings bellow-

| Features | Settings |

|---|---|

| Tungsten Diameter | Same as butt joint |

| Torch Cup | Same to butt joint |

| Amperage | Ranging from 60-70 |

| Gas | Gas & flow rate would be same as butt joint that is argon at 15cft. |

| Filler Electrode | 1/16 inch |

| Weld Speed | 10″/minute |

Corner Joint

In corner joint, one piece of metal is placed over another pieces corner perpendicularly like English alphabet ‘L’. Then welded the join area for attach them together.

To corner weld 1/16″ aluminum follow the settings bellow-

| Features | Settings |

|---|---|

| Amperage | Ranging from 55 to 65 |

| Speed | Should be 12inch per minute |

Fillet Joint

In Fillet joint one piece of metal is place perpendicularly or in 90 degree angle over another metal. Then two pieces are welded together.

To fillet joint 1/16″ aluminum follow the settings bellow-

| Features | Settings |

|---|---|

| Amperage | From 55 to 75 |

| Speed | 10″per minute |

Lastly

1/16 inch aluminum is thinner metal. You must be careful about welding settings and most importantly you must pay attention to welding speed and amperage. You can see in butt, lap, fillet and corner joint requirements that amperage and speed of welding changes but other settings remains the same in most of the cases.

Note: wear proper safety equipment while tig welding and try not ever to touch the welded metal after welding.

Sources