Tig welding is clean, energy saving and flexible among all other welding techniques. Tig provides strong joint at the same time less spatter. You can use tig welding to weld aluminum, stainless steel, magnesium alloy and even chromoly easily.

Though tig welding is costly technique, you can lower the cost by following some tig tips and by configure the welder to a guided settings.

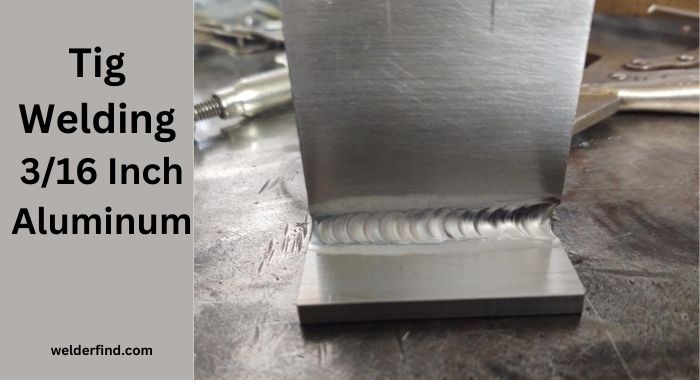

Today we will talk about what welding settings you need to tig weld 3/16″ aluminum.

3/16 Inch Aluminum Welding

We know that aluminum is a non-ferrous metal which makes them rust resistant metal. Aluminum is an useful metal used in different applications ranging from trailer of trucks to aerospace engine block.

3/16″ aluminum is thinner than 1/2 ” aluminum but thicker than aluminum sheet. To tig weld 3/16″ aluminum plate you may follow the welder settings similar to tig welding 1/2″ aluminum.

You may use 190- 250 amp tig welder, with 3/32″ tungsten (2% Lanthanated), argon gas @ 20-25 cft and torch cup of 7/16″- 1/2″ diameter for t-joint. This settings would help your welder to generate weld puddle started earlier saving tungsten and filler rod.

Bellow we we have discussed the welder settings for different joints.

Butt Weld 3/16″ Aluminum

The settings for butt welding is as bellow-

| Features | Settings |

|---|---|

| Tungsten Diameter | Traditional Sqaurewave machines would need 2% ceriated orange tungsten to weld 3/16″ aluminum. You may use pure tungsten too. For Inverter, 2% ceriated is the best. Ball the tungsten before welding. |

| Balance | Maintain the balance to 70% or more for butt joint. |

| Frequency | Frequency should not less than 100hz. |

| Torch Cup | Use 7/16″-1/2″ ceramic torch cup for starting puddle earlier |

| Filler Metal | Filler metal of 3/32″ would be enough |

| Amperage | Amperage of the welder can be between 125-150amp. You may use more amps but decrease the frequency in the case. Use Ac tig welder for butt welding 3/16″ aluminum. |

| Gas & flow rate | Use argon gas @ 21cft for better puddle |

| Travel Speed | You may go at 11″/m speed to weld perfectly |

Lap Weld 3/16″ Aluminum

| Features | Settings |

|---|---|

| Tungsten, frequency & balance | To lap join, you may follow the same settings as butt joint for tungsten that is 2% ceriated tungsten. Frequency at 100hz or more and balance 70%. |

| Torch cup | Same settings as butt joint |

| Filler | 3/32inch |

| Amperage | Amperage range should be between 130-170a amps |

| Gas and flow rate | Same as butt joint |

| Travel Speed | Should be 9″/m. |

Corner Weld 3/16″ Aluminum

| Features | Settings |

|---|---|

| Tungsten, frequency & balance | Same as butt and lap joint settings |

| Torch cup | From 11.1 to 12.7mm |

| Filler | Same as butt joint |

| Amperage | Ac tig welder with 130-160amp power |

| Gas and flow rate | Argon gas to be used with 21cft |

| Speed | 11 inch/minute |

3/16″ Aluminum Fillet Joint

| Features | Settings |

|---|---|

| Tungsten, frequency & balance | Don’t need to change. Set them as butt and lap joint’s configuration |

| Torch cup | Also don’t need to change |

| Filler | Don’t need to change |

| Amperage | In the case of fillet welding 3/16inch aluminum, you may use 150-180amp power in Ac current flow. |

| Gas and flow rate | Same as the butt and lap |

| Speed | 9 inch/minute |

So, we can see that you can tig weld 3/16″ aluminum with same tungsten, torch cup, gas and gas flow rate and filler metal. Settings only change are amperage & travel speed. So try to choose a tig welder that can weld with power between 130-250amps.

You may buy a welder that can be more than the mentioned amperage for multiple use and the decision is best from my view point. Just look for whether the welder comes with foot paddle facility or not. Welder with foot paddle is best for flexible use.

Lastly

I hope that the article has solved your problem of choosing welder and other settings to weld 3/16″ aluminum. It is really a fun to weld 3/16″ aluminum if settings are perfectly set.

Thanks for reading and check out other related articles bellow.