Welding rods have different numbers imprinted on them. The numbers indicate whether the rod is good for deep or light penetration, it produces a lot of heat or not, or the number of puddles. Also, different numbers of welding rods are specialized for different material jointing.

Among different welding rod types, there is 6011 welding rod which is very much like 6010. The good thing about 6011 is that a lot of modern inverters run at 6011. So, this welding rod is pretty handy.

Our Selected Top E6011 Welding Rods

Here, we’ll like to present the five best 6011 welding rods according to our market and performance analysis. Different welding rods are good and popular for different reasons; surely those will catch your attention.

| Products | Name | Description | Latest Price |

|---|---|---|---|

| Forney E6011 Welding Rod | Country of Origin USA Size 3/32-Inch Material Mild Steel Capacity Description 60,000 Tensile strength | Check Price |

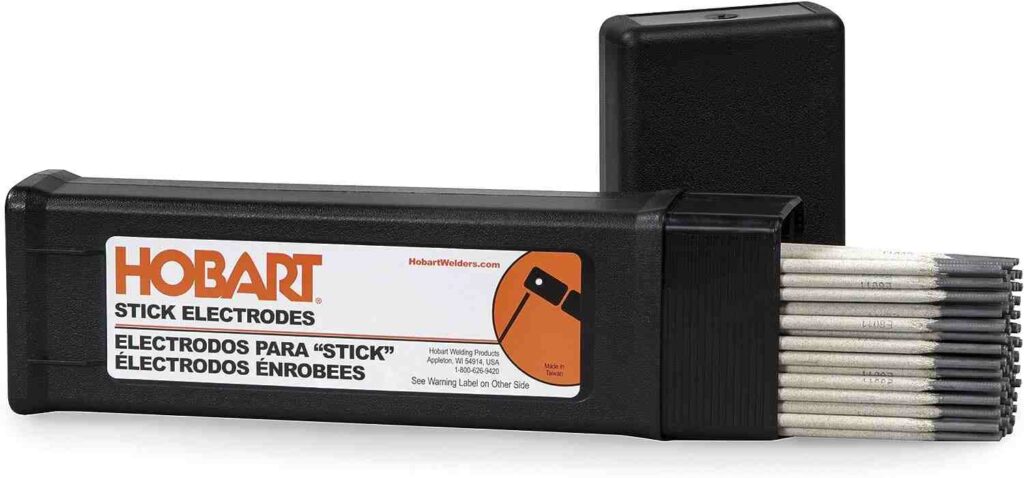

| Hobart E6011 Stick Welding Rod | Country of Origin USA Size 5/32-5lbs Item Weight 5 pounds | Check Price |

| Weldcote Metals E 6011 Welding Rod | Size 3/32-5 lbs Item Weight 5.19 pounds Material Cellulose coated Special Features Low Manganese Emission, Patent Protected | Check Price |

| Blue Demon E 6011 Welding Rod | Country of Origin China Item Weight 50.9 pounds Size 1/8″(Diameter) | Check Price |

| K-T Industries E6011 Electrode | Country of Origin China Item Weight 5.16 pounds Material Metal Power Source ac/dc | Check Price |

Forney E6011 Welding Rod

Forney was in the welding rod business even long ago, before most of our birth. They have their network spread like a spider net all over the country. And most importantly, their customer service is very much resolved to solve any issues willingly.

So here we have a 3/32 inch 1 pound 6011 welding rod from Forney; no doubt this is an all-position welding road that ensures fast freezing on painted, dirty, and rusty metal surfaces. This welding road has a mild steel core that produces strong arc force deep penetration.

The most unique feature Forney 6011 holds is the unique flux doubles with coated brazing alloy with unmatched arc stability. It only bothers to join aluminum in some positions.

Pros

- Minimal surface preparations are needed

- Good for all positions welding.

- Ideal for AC and DC operation

Cons

- Some need to be scuffed up on the floor before starting to melt down.

Reasons behind Buying Forney 6011

First of all, the company is very trustworthy and has been running this business for a long time. And also, their customer service is responsive. It saves a lot of time making the surface ready. That’s something commendable.

What’s So Special

The unique flex makes the deep penetration more active.

Check Forney E6011 Welding Rod Price At Amazon

Hobart 770462 6011 Welding Rod

Another welding brand has been in the market for over a century. Hobert makes sure they design and tent the welding road properly before allowing them in the market.

Welding with Hobart 6011 has a special use on carbon and galvanized steel. You can do it in all the positions. It ensures all the features of 6011 are available, like deep penetration, no issue on welding through light and medium amounts of dirty metal pieces.

Pros

- Weld had hot and freeze timely too

- Runs on both AC and DCEP polarity

- Excellent penetration.

Cons

- The plastic case will break if it slips out of hand and falls on the ground.

Reasons Behind Buying Hobart 6011

It is like what it always was. The welding motion never changes; you must feel the same as always. And the puddle gets frozen pretty quickly.

What’s So Special

The hobart 6011 is a deal breaker for continuously welding on dirty surfaces.

Check Hobart E6011 Welding Rod Price At Amazon

Weldcote Metals E6011 Welding Rod

If you are looking for a low manganese electrode, weldcote is the best option for you. For the last several decades, many welding brands have been decreasing the exposure of Mn components. This is great news for both the welding community and environment lovers.

So, the weldcote low manganese rod has a unique flux composition with a lower amount of Mn, and while welding it decreases the manganese emissions by up to 60%. The arc-grade rods penetrate through a rusty, thick layer of dirt, reducing exposure. You will feel pretty smooth while doing strokes and re-strokes with this road,

Pros

- Ensures flawless joints.

- Industry level welding ridas.

- Provides smooth welding.

Cons

- The whip and come back motion while welding looks tougher.

Reasons Behind Buying Weldcote 6011

It is environmentally friendly, and it is easy to start and re-start the welding. Also, their customer service is good enough.

What’s So Special

Welding looks fun using it. If you cross-section any piece of metal you welded with this one, you’ll see the welding reaches at the very bottom or very top.

Check Weldcote E6011 Welding Rod Price At Amazon

Blue Demon E6011 Welding Rod

Blue Demon is a very fast freezing and fast heating welding rod. It mostly works on every position, like vertical and overhead. The unique thing it has is the light slag that eliminates the slaves’ holes.

Thus, the electrode rod’s weld is very good. The Blue Demon was primarily designed to use on AC power sources as it produces strong acr force and deep penetration.

Pros

- Does a good job on dirty surfaces.

- SHip building quality.

- Good value for money.

Cons

- It sticks on the surface until it is not warm enough.

Reasons Behind Buying Hobart 6011

It asks a much lower price than others, in its one box you will get almost three times more road with spending a little more money.

What’s So Special

The rods get heated up quickly and come in a tube so they don’t get damaged.

Check Blue Demon E6011 Welding Rod Price At Amazon

K-T Industries E6011 Electrode

The K-T industry is mostly committed to providing something exceptional in quality and simplicity for users. Like that, the K-T 6011 welding rod offers unmatched operator appeal. This one is specially designed for AC power sources. Furthermore, its performance shines from the light sheet metal fabrication to galvanized steels, shipyards, and construction grade steels.

Pros

- All positions are versatile and versatile

- Wide range of Application.

- Better control while welding.

Cons

- The welding is not always precise.

Reasons Behind Buying Hobart 6011

The 82000 psi tensile strength and operating temperature for 1/8 “requires 80-120 amps. These are the actual deal breakers.

What’s So Special

The rapid solidification of the weld metal is one of the greatest strengths of K-R 6011’s—minimum risk for vertical and overhead welding.

Check K-T E6011 Welding Rod Price At Amazon

Understanding 6011 Welding Rods

To understand the 6011 welding rod, you must know the different welding rods have different purposes to serve. And also, if the purpose is similar to other rods, the welding rod’s coating composition may be different.

Here are the basics difference we see from other roads:

Electrodes Coating: Cellulose

Current: Both AC/DECP

Penetration: Deep

Deep penetration helps it to join two metals like they were always joined. Also 6011

can do its work on dirty metal, paint, and galvanized surfaces.

Brief Overview of 6011 Welding Rods

6011 welding rod is mostly used in shielded metal arc welding, commonly known as stick welding.

Polarity: The 6011 electrodes can be used with both DC and DCEP and DCEN polarities. This kind of versatility allows it to be used on various welding machines.

It is also suitable for welding in all positions. Both vertical and overhead positions are relatively easy to weld.

Penetration: It is popular for deep penetration and dirty surface penetration. While 6010 can also do deep penetration, it that can’t penetrate through rust, paint, and contaminants on the metal. So overall, it’s a fast freeze super high penetration welding rod.

Skill Level: This rod is popular among beginners and even experts. But the welding technique is no different than 6010; you must do it with a bit of whip and pause motion with a 6011 rod. You should go two electro diameter front and then come back one electro diameter.

You can control how much penetration and how much cool off the puddle with your strokes if you maintain the proper welding techniques. If you come out of the puddle and then back, by the time the puddle cools off, if you make come out of the puddle for a very short distance and go back, it will be a small and slow-motion dig and deeper penetration.

Composition and Classification

The 6011 welding rod is classified from AWS (American Welding Society) as E6011 electrodes. Here, E stands for Electrode and 60 indicate the tensile strength is approximately 60,000 psi.

The composition of the 6011 welding rod includes both a core wire and a flux coating. No wonder the core electrode is made of mild steel, and it is very much compatible with a wide range of base metals. It is even compatible with carbon steel and mild alloys.

The flux coating consists of cellulose; mostly, it comes from organic material such as plant fibers. The deep penetration is assisted by cellulose coating. Furthermore, it creates a gas shield around the arc. So we can have smooth and effective welding.

Key Features of the 6011 Welding Rods

- Most of the brand’s 6011 welding rods are ready to weld all positions vertically and overhead

- Work seamlessly on both DC+ and DC- settings. Also works in AC power sources.

- Ideal for light sheets galvanized steel, shipyard sand construction steel welding.

- It can operate in broad amperage. 80-120 amps for 1/8 “size electrodes.

Tips for Welding with 6011 Rods

- For 6011, sticking to a consistent arc length is important. 1/8 “to 1/4 “is the consistent length. Too short an electrode may stick, and too long will have less penetration.

- Always do a steady movement; we suggest you do whip and comeback movement while welding. If you go 2mm front, come back .5 mm back.

- After welding one side, give some to the steel sheets or metals. For 6010 or 6013, you aren’t required to give this time. But for better penetration, 6011 requires a pause.

Conclusion

We always say practice, patience, and experience are needed for being a good welder. If you have never used 6011 before, try to practice the motion and pause with some useless metals. For welding, adaptation is what every welder requires.