Many factors combined deliver satisfactory welds and maximized performance, so your structure doesn’t lack the proper finish or sturdiness.

With that being said, it’s apparent that you need to understand what elements can give you those optimized results. And what you need to weld your metal to the satisfactory level.

Today we will talk about tungsten rods for best tig welding result specially to weld aluminum.

Professionals are welcome, too, as we will talk about some of the best tungsten for welding aluminum on the market.

So, without further ado, let’s see what the fuss is about and why you need these all-rounder products.

Top 5 Best Tungsten For Aluminum Welding

| Product | Name | Description | Price |

|---|---|---|---|

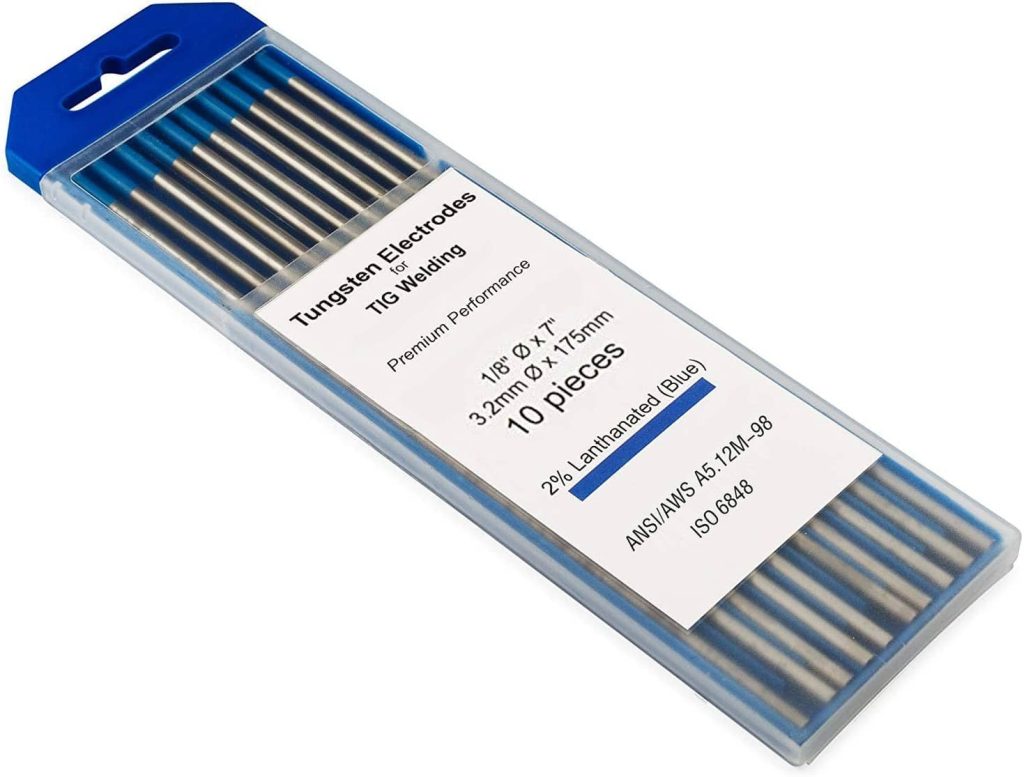

| Midwest TIG Welding Tungsten Electrodes | Package Dimensions 8.07 x 2.28 x 0.28 inches Item Weight 5.9 ounces Size 3/32″ Material Blue – 2% Lanthanated | Check Price |

| Yeswelder Tig Welding Tungsten Electrodes | Package Dimensions 8.07 x 2.36 x 0.47 inches Item Weight 4.6 ounces Size 5pk 1/16″ & 5pk 3/32″ Color Blue | Check Price |

| Midwest Tig Welding Green Tungsten Electrodes | Package Dimensions 8.03 x 2.32 x 0.28 inches Item Weight 3.2 ounces Size 1/16″ Material Green – Pure Tungsten | Check Price |

| KingQ Tig Welding Tungsten | Package Dimensions 8.1 x 2.1 x 0.3 inches Item Weight 9.6 ounces Material 2% Lanthanum tungsten Size 1/8″ | Check Price |

| GENSSI TIG Welding Tungsten Electrode | Item Weight 6 ounces Color 1/16 (1.6mm) inch blue WL20 | Check Price |

Detailed Product Review

Ready to meet the best tungsten for aluminums? Here are our top picks that we’ve selected after thorough research, test-runs and spot-on results.

Don’t fall behind on the game and take a look at these show-stoppers and their standout features.

To be fair, there’s no alternative to such vital components while welding aluminum. So, if you’re an amateur who knows nothing about the importance of tungsten and its capacities, stay tuned.

1. Midwest TIG Welding Tungsten Electrodes 2%

Features

First off, the Midwest tungsten has a comprehensive collection of types and sizes. So, you can take your pick and purchase one that refers to your needs. The products can complement stainless steel, titanium alloys, nickel alloys, copper alloys, and other types of metals.

It’s manufactured and engineered to perfection. Thus, you acquire high-quality and long-lasting electrodes that can perform even the most challenging welds time and again. Sounds great, doesn’t it?

The premium 10-pack rods for welding are also the easiest to use for any skill set. And as if that wasn’t enough, the results with this piece hit the bull’s eye every time, no matter the kind of metal you’re working with.

Good sides

- Has extremely high accuracy

- Easy to use by all expertise levels

- Made with high quality materials and packaged in an easy-open box

- comes in multiple material types and sizes

- MSDS, AWS and ANSI certified

Bad sides

- Best not to use on thoriated electrodes

Why should one buy this one

The Midwest tungsten is exceptional for those who want to achieve high accuracy in their results by exerting less to no effort on their end. It will make your projects smoother with spotless results.

Why it is special

It’s a remarkable piece due to its high reliability, unmatched durability, low burning rate, and precise arc strike. It also refers to AWS and ANSI standards.

Check Midwest TIG Welding Tungsten Electrodes At Amazon

2. YESWELDER TIG Welding Tungsten Electrode 2%

Features

As we all know, lanthanated electrodes provide unparalleled ease while achieving arc strikes and lower amps.

Moreover, this assorted set also performs incredibly on both AC and DC applications, along with results that have a professional finish every time, even if you’re an amateur.

New and old users never doubt its performance for a second, mainly because it’s AWS standardized.

The premium 10-piece set has 2% electrodes lanthanated with 7″ length and seven sizes. But that’s not all; you can also pick your favorite color as it offers six different hues.

Good sides

- Comes in 6 colors and 7 sizes with different price ranges

- Made with high quality products to extend sturdiness

- Has spot-on accuracy during welds and in outcomes

- Relatively easy to use by all

Bad sides

- Some users think that they don’t last as long as they should

Why should one buy this one

One of the critical features of this tungsten lanthanated assorted pack is that they never oxidize, which minimizes the risks and chances of corrosion.

Why it is special

The tungsten set is extremely easy to sharp and even easier to clean up after. Moreover, they provide seamless results on all welding procedures and sizes.

Check Yeswelder Tig Welding Tungsten Electrodes At Amazon

3. Midwest TIG Welding Tungsten Electrodes Pure Tungsten (Green, WP)

Features

According to the average ratings that this Midwest green tungsten has received, everything lies around 4.8 stars.

Now, if you’re an avid lover of tungsten that performs accurately and with unparalleled longevity, you’re in for a fine ride with this piece.

These tungsten are the easiest to use; however, they might require some learning curve and adjusting if you’re an amateur.

Another big hit with this product is that you attain a higher value than the price you pay. The highly-rated and reviewed tungsten also has MSDS and AWS standard certifications.

Good sides

- Best for AC applications and aluminum and magnesium alloy

- Comes with long-lasting electrodes for coherent performance

- Has high-quality arc and low burn-off range

- Made with 99.95% pure tungsten for high accuracy

Bad sides

- The 2% lanthanated electrode doesn’t hold up as well as the thoriated one

Why should one buy this one

This Midwest tungsten set is the right deal for you if you’re looking for engineered exact specifications that provide coherent results on every material even after years of regular use.

Why it is special

The specialty in this pack has to be its 100% pure tungsten electrode construction. You get professional results every time with stunning craftsmanship at an extremely valuable price.

Check Midwest Tig Welding Green Tungsten Electrodes At Amazon

4. KINGQ TIG Welding Tungsten Electrodes 2%

Features

Who doesn’t want the perfect engineering in their staple welding tungsten, right? If you’re no different from this craving, you’ll love this welder best friend, which has been manufactured specifically to attain pinpoint specifications.

This 2% thoriated red, ten-pack has all the long-lasting capacities you’ll ever need in your toolbox.

No matter how many times you use the set over the years or regularly, it will never disappoint with wavering performance.

The low burning rate and high arc strike also conjoined these tungstens’ highest maintenance and quality.

Good sides

- Made to last the longest time

- A staple product for DC welding due to high durability

- Extremely easy to get used to and utilize

- Best for non-corrosive and low-alloyed steels

Bad sides

- None

Why should one buy this one

Grab these if you want to work with DC application solely and mainly on elements such as non-corrosive and low-alloyed steel.

These perform seamlessly and with professional-grade excellence on materials like titanium, copper, nickel, magnesium, and aluminum.

Why it is special

One of the most acknowledged specialties in this best tungsten for aluminum has to be its durability and long-lasting capabilities. No matter your task, the ten-pack will surely get the job done.

Check KingQ Tig Welding Tungsten At Amazon

5. GENSSI TIG Welding Tungsten

Features

This TIG welding tungsten by Genssi comes in a blue tone. However, it might even give off a greenish tint at the tip at times.

The 1/16-inch all-rounder is built with premium quality materials and caters to 2% lanthanated electrodes.

Once you know your requirements for your projects and match them with the revolutionary specifications that this set has to offer, you can be all set for a lifetime.

And as if that’s not enough, you can also refer to its size chart, which offers around six different measurements and material types for your ease of use and compatibility. The Genssi offers multiple materials and corresponding colors at different pricing to pick them according to your specific work demands.

Good sides

- Comes in 3 different colors with varying price points

- Has amazing concentrative ground finish

- Performs with high reliability and consistency

- Built with sturdy and high-quality materials

Bad sides

- The tip tends to melt at lower settings

Why should one buy this one

Look no further if you’re in dire need of premium quality tungsten. The 2% lanthanated Genssi welding tungsten has on point construction, making your welding jobs quicker and more accurate.

Why it is special

Genssi tungsten has a specific and concentrative ground finish at the tip and along the length. This makes the product perform coherently, whether it’s a minor DIY or a significant project.

Check GENSSI TIG Welding Tungsten Electrode At Amazon

What Can I Do Prevent Tungsten Form Splitting

Generally, split tungsten arises from a faulty machine problem, not an electrode issue. To avoid this issue, users can set the balances to 75% minus and 25% plus, along with a frequency of 75Hz.

They should also grind the tip at a 60-degree angle with which the tip will be a bit warm, thus, providing more excellent stability. A flattening of 1mm is acceptable with the starter current set at the lowest setting for three components of tungsten and a maximum of five for others.

How Do I Prepare The Tungsten For Welding

One of the most critical steps in tungsten welding is choosing the correct tool and preparing it. If you slack back in this sector, you will attain underwhelming results. So, here’s how you can prepare your tungsten for optimized results.

Start by grinding the end to a pointy finish. The grinding should run along the length and towards the tip. This provides excellent arc starts and reduces arc wander-offs.

This grinding technique is applicable for both AC and DC settings. While the AC application will set into a blunt or round finish, the DC will have a pointy one. However, it also varies from user to user and their project needs.

Why Is Tungsten Better Than Other Metals To Weld Aluminum?

Tungsten inert gas (TIG) or gas tungsten arc welds (GTAW) is the most outstanding choice for aluminum welding. Its high application has multiple reasons, mainly because it protects the welding pool.

It’s worth it because of its 3410-degree C higher melting point.

Tungsten is a rare element with a specific dedication to GTAW electrode welding. The entire process relies heavily on high-temperature resistance and tungsten’s hardness to carry the current through to the arc.

Moreover, GTAW for aluminum welding doesn’t require mechanical wire feeds, which could lead to feeding problems.

What Are All The Factors To Be considered While Selecting A Tungsten Rod To Weld Aluminum

Acquiring the best tungsten for aluminum isn’t a piece of cake. You need extensive knowledge on the matter before you hop on to add some to your shopping cart. First off, you need to decide on the tungsten type you require.

So, come and gander at those related factors before selecting an item.

1. AC and DC inverter

DC refers to Direct Current, whereas AC stands for Alternating Current. While working with welders either of these two are included.

AC changes the flowing of the currents, whereas DC doesn’t. Additionally, tungsten rods have varying heat resistance.

Thus, there remain no hazards with AC, but DC tungsten tends to burn most of the time.

2. Kind of metal and alloy

It’s a no-brainer that the kind of metal plays a significant role when choosing tungsten.

If, for example, aluminum in the metal base, users will have to find tungsten that will have corresponding properties to accompany the aluminum project.

3. Kind of weld

Once the users understand the preliminary requirements and try to match the features with the inverter and metal, they will also need knowledge and guidance to pick a weld type.

The rods need to be according to a similar suit of welding.

Advantages Of Choosing The Right Tungsten For Aluminum Welding

We wouldn’t be stressing about the importance of good quality tungsten if it didn’t have some obvious and underlying advantages.

In this section, we will talk about the benefits of the best tungsten for aluminum that you need right away.

1. To maximize benefits

You will acquire optimized results and smooth performance if you select the right rod by referring to the correct inverter.

Tungsten varies based on the materials they can tailor to and own construction. Thus the effects may be different if picked incorrectly.

First, decide on the inverter settings and then choose tungsten that can match and carry out the configurations and optimized benefits.

2. To acquire quality weld

Once again, tungsten doesn’t necessarily have to be pure to serve you with high-quality welds depending on the current type.

The rightly picked tungsten will ensure smoother welds and vice versa.

3. To avoid post clean up mess

Unfortunately, if you fail to purchase the right piece for yourself, it can create a bigger mess than anticipated. Moreover, the entire welding process will be underwhelming, too, in that case.

Various Kinds Of Tungsten Selection Available In Welding

If you’ve been looking at tungsten for a while, you’d know that a couple of different colors and sizes of welding tungsten for aluminum are available in the market. But, what do the colors mean, and what do these different types of tungsten specialize in? Let’s find out.

1. Pure tungsten

Green electrodes resemble pure tungsten.100% pure tungsten is preferable for balling and arc stability when heating the objects. They’re also referred to as ‘clean welds’ because of their specifications.

Additionally, pure tungsten is also the best tungsten for aluminum because they’re incredibly cheap. However, these are only applicable to DC aluminum welding.

2. 2% ceriated

These are grey in color and contains 2% cerium. Generally, 2% ceriated electrodes are utilized for DC welding with lower amperage.

Moreover, these are highly renowned for their unyielding durability. They get the job done perfectly in complicated welding applications and AC welding too.

3. 2% lanthanated & 1.5% lanthanated

2% lanthanated will endure better amperage than the rest of the electrodes. These have a blue tint and accompany well while alloy welding, specifically aluminum. 2% lanthanated also suit thinner sheets of aluminum due to the lower amperage.

On the other hand, the 1.5% lanthanated has a golden color and is also suitable for aluminum welding. But, 2% lanthanated electrodes handle heat better than the others; thus, has a higher preference.

4. 2% thoriated

2% thoriated is the least selected electrode. This is because of the radioactive that they’re known to have.

These have a red identification and can also cause inconsistent results during welding along with the radiation risks.

5. 0.8% Zirconiated

0.8% zirconiated electrodes are white and used for welding aluminum with AC applications.

They have lower heat resistance and are suitable for balling up. However, 0.8% of zirconiated electrodes have a short lifespan and low current capability in comparison.

6. Rare Earth Mix

Rare earth is often substituted with thoriated tungsten. They come in a purple color and have an abundance of high-grade qualities.

Since the other is notorious for its radiation, rare earth is becoming a user favorite recently.

Faq (Frequently Asked Question)

What color tungsten do you use for aluminum?

Pure tungsten has a green hue and provides impressive arc stability for AC wave welds on magnesium and aluminum, especially.

Is Lanthanated tungsten good for aluminum?

Even though thoriated is renowned, it has a few setbacks, such as producing radiation. At the same time, lanthanide tungsten doesn’t do so. Lanthanated tungsten works amazingly for aluminum welding or any other metal.

Which tungsten is traditionally only used for aluminum?

Generally, zirconiated or pure tungsten electrodes are utilized for AC aluminum welding. Experts recommend not using 2% thoriated tungsten electrodes.

Furthermore, you must ensure that the tungsten electrode’s diameter is significant enough to carry the welding you’re opting for. AC weldings usually require a larger diameter.

Is purple tungsten good for aluminum?

Rare earth purple tungsten offers suitable welding and ignition properties. These are universal and support various applications within the AC and DC welding coverages of magnesium alloys, copper, nickel, titanium, aluminum, and steel

Last Words

Now, that’s a wrap on this detailed article about the best tungsten for aluminum. It’s safe to say when you need optimized results, you need the correct tools for it. And in order to obtain seamless results on the aluminum welds, you need high-quality and functioning tungsten to accompany it.

But more than that, people love that they can quickly avert risks with these high-performing tungsten, and to be honest, that is one of the best hits that every expert and DIYer raves about.

We hope you get to experience that relief soon too. We’ve spent hours searching for the best tungsten to get your job done. So, if you purchase one with total clarity and match your requirements with the features, you’ll be all set!

Thanks for one’s marvelous posting! I truly enjoyed reading it, you happen to be

a great author. I will be sure to bookmark your blog and may

come back someday. I want to encourage you to definitely continue your great writing, have a nice weekend!

Spot on with this write-up, I actually believe that this amazing site needs

a great deal more attention. I’ll probably be back again to read through more, thanks for the info!

Thanks and keep reading..

First of all I would like to say fantastic blog! I had a quick question in which I’d like to ask if

you do not mind. I was curious to find out how you center yourself and

clear your thoughts before writing. I’ve had a difficult time clearing my mind in getting my thoughts out there.

I truly do take pleasure in writing however it just seems like the first 10 to 15 minutes tend to be wasted

just trying to figure out how to begin. Any ideas or hints?

Kudos!

For writing a blog I take time to plan and organize the information. I make a short checklist and format for each blog post I write and post after I have edited and proofread several time. I brainstorm the topic collect information and start writing. That’s simple.