WelderFind for Welding Lover

Welding Guides, Tips & Tricks

Tig Welding Basics

- How To Tig Welding Aluminum For Beginners

by James Smith

by James Smith - Do You Need A High-frequency To Tig Weld Aluminum

by James Smith

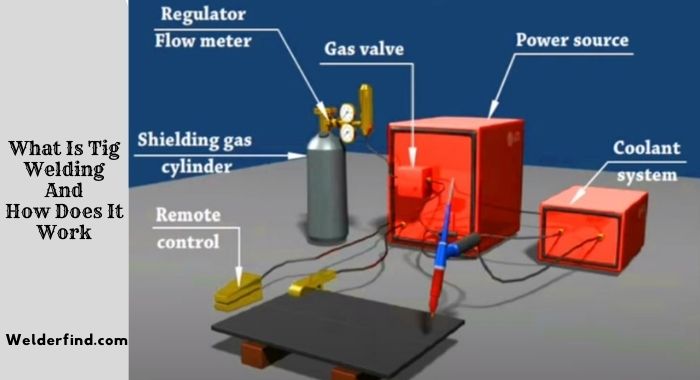

by James Smith - What Is Tig Welding And How Does It Work

by James Smith

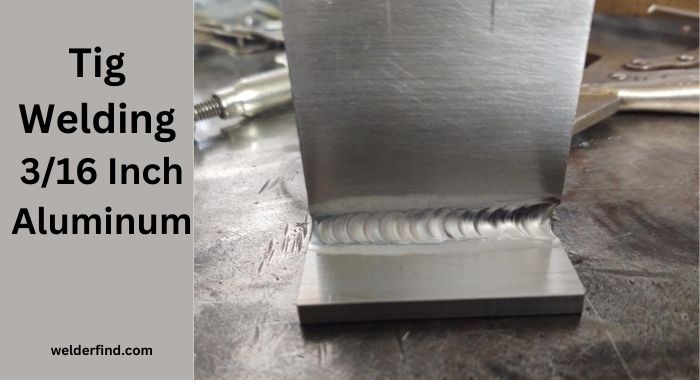

by James Smith - Tig Welding 3/16″ Aluminum

by James Smith

by James Smith - Tig Welding 1/2 Inch Aluminum (Settings For Tig)

by James Smith

by James Smith - Types Of Tig Welding

by James Smith

by James Smith

Tig Welders

- Best Tig Torch For Pipe Welding

by James Smith

by James Smith - Best Respirator For Welding Galvanized Steel

by James Smith

by James Smith - Top 6 Best Tig Welder For Aluminum (Tested & Picked)

by James Smith

by James Smith - 5 Best Tungsten For Aluminum Welding (Picked After Researching 20 Products)

by James Smith

by James Smith

Stick Welding Basics

- Can You Stick Weld Aluminum

by James Smith

by James Smith - Can You Stick Weld in The Rain

by James Smith

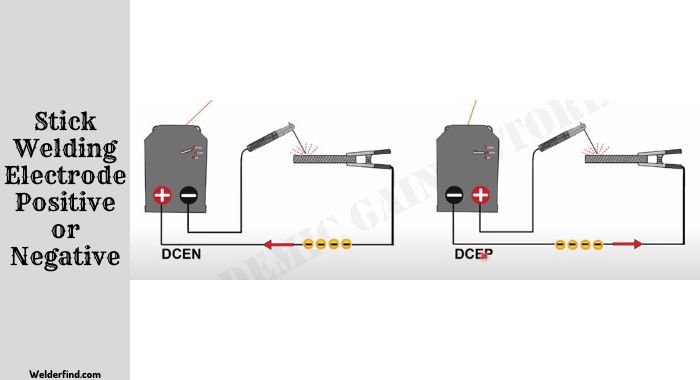

by James Smith - Stick Welding Electrode Positive Or Negative

by James Smith

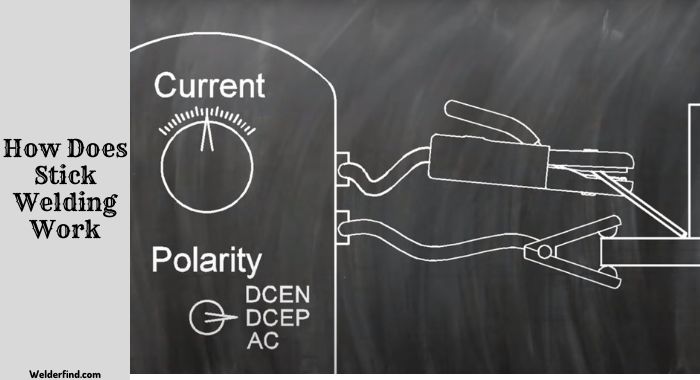

by James Smith - How Does Stick Welding Work

by James Smith

by James Smith - Stick Welding Tips For Beginners (The Basics)

by James Smith

by James Smith - Can You Stick Weld Magnesium

by James Smith

by James Smith

Top Welder Machines

- Best Welder For Pipe Fenceby James Smith

- Best Welder for Motorcycle Framesby James Smith

Beginner Info

- How To Build A Pipe Fence

by James Smith

by James Smith - How To Weld Galvanized Steel With A Mig Welder

by James Smith

by James Smith - Is Welding Galvanized Steel Dangerous

by James Smith

by James Smith - Can Welding Galvanized Steel Kill You

by James Smith

by James Smith - Can You Weld Copper To Aluminum

by James Smith

by James Smith - Cc Vs. Cv Welding – Which One is Better?

by James Smith

by James Smith